| Product-Name |

Butybond AB15 |

Solabond FS15 |

Solabond FSP18 |

Solabond FS18 |

Solabond PSP15 |

Thermobond STP18 |

Thermobond QTP18 |

Thermobond RT21 |

| General Description |

|

|

|

|

|

|

|

|

| Base coat |

mod. Polyurethane |

mod. Polyurethane |

mod. Polyurethane |

Polyesterimide |

mod. Polyurethane |

mod. Polyurethane |

mod. Polyurethane |

A200 + Polyamidimide |

| Bond coat |

Polyvinylbutyral |

Polyamide |

Polyamide |

Polyamide |

Polyamide |

Polyamide |

Polyamide |

aromatic Polyamide |

| IEC (including the following standards) |

IEC 60317-35, 60317-2 |

IEC 60317-35, 60317-2 |

|

IEC 60317-36 |

IEC 60317-35, 60317-2 |

|

IEC 60317-35 |

IEC 60317-38 |

| NEMA (including the following standards) |

MW 131-C |

MW 131 |

|

|

MW 131 |

MW 131 |

MW 131 |

MW 102 |

| Diameters available |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.015 - 0.50 mm |

0.015 - 0.50 mm |

| Properties |

Low bonding temperature, wide process window, non-hygroscopic |

All bonding methods applicable, good processability, hygroscopic (not suited for humid regions) |

All bonding methods applicable, good processability, hygroscopic |

Solvent bonding possible, high resoftening temperature, high thermal and mechanical properties of base coat, hygroscopic thus not suitable for Asia |

All purpose selfbonding enamel, wide process window, high bonding strength, thermosetting applicable, non-hygroscopic |

Good winding ability, thermosetting applicable |

higher thermal and mechanical properties, very high resoftening temperature after thermosetting |

very high thermal and mechanical properties, very high resoftening temperature |

Shelf life in months (at 25°C /

60% rel. humidity) |

≤ 6 |

≤ 3 (hygroscopic) |

≤ 5 (hygroscopic) |

≤ 5 (hygroscopic) |

≤ 6 |

≤ 6 |

≤ 6 |

≤ 6 |

| Applications |

Stepping motors for quartz watches, instrument coils, voice coils, Sensors, Transponders |

Loudspeakers, small motors, sensors, Transponders |

Loudspeakers, small motors, sensors, Transponders |

Loudspeakers, small motors, sensors, Transponders |

Instrument coils, loudspeakers, vibration motors, sensors, receiver and speaker for mobile phones |

High power speaker, vibration motors |

high power speaker and receiver, micro speaker, high temperature applications |

motors, loudspeakers |

| Thermal values of base coat |

|

|

|

|

|

|

|

|

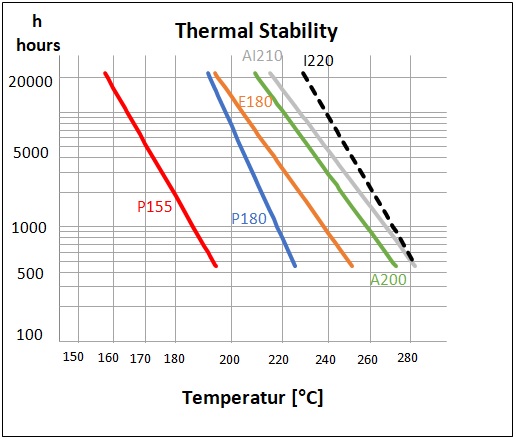

| Temperature index 20.000 h acc. to IEC 60172 |

158°C |

158°C |

192°C |

195°C |

158°C |

192°C |

192°C |

212°C |

|

Thermal stability chart [view]

|

|

|

|

|

|

|

|

|

| Cut through temperature |

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-6 4 |

≥ 200°C |

≥ 200°C |

≥ 230°C |

≥ 265°C |

≥ 200°C |

≥ 230°C |

≥ 230°C |

≥ 320°C |

| Elektrisola typical value |

225°C |

225°C |

260°C |

315°C |

225°C |

260°C |

260°C |

365°C |

| 0.25mm: acc. to IEC 60851-6 4 |

≥ 200°C |

≥ 200°C |

≥ 230°C |

≥ 265°C |

≥ 200°C |

≥ 230°C |

≥ 230°C |

≥ 320°C |

| Elektrisola typical value |

230°C |

230°C |

265°C |

325°C |

230°C |

265°C |

265°C |

380°C |

| Heat Shock |

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-6 3 |

≥ 175°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 220°C |

| Elektrisola typical value |

190°C |

190°C |

210°C |

260°C |

190°C |

210°C |

210°C |

250°C |

| 0.25mm: acc. to IEC 60851-6 3 |

≥ 175°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 220°C |

| Elektrisola typical value |

180°C |

180°C |

200°C |

250°C |

180°C |

200°C |

200°C |

240°C |

| Electrical values |

|

|

|

|

|

|

|

|

| Low voltage continuity for Grade 1B wires |

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-5 1 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

| Elektrisola typical value |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| High voltage continuity for Grade 1B wires |

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| 0.25mm: acc. to IEC 60851-5 2 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

| 0.25mm: Elektrisola typical value |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

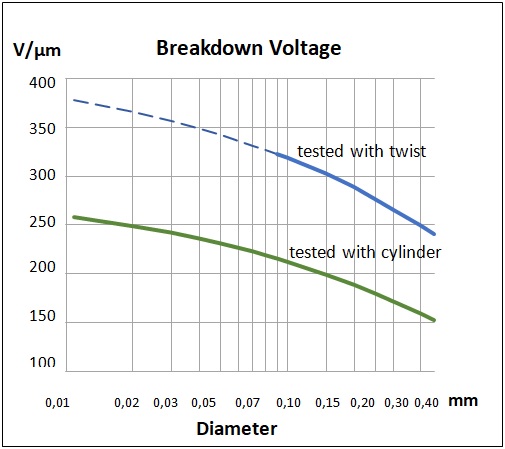

| Breakdown voltage acc. to IEC 60851-5 4 (at 20 °C, 35% humidity) |

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

160 V/µm |

160 V/µm |

160 V/µm |

160 V/µm |

160 V/µm |

160 V/µm |

160 V/µm |

160 V/µm |

| 0.25mm: Elektrisola typical value |

120 V/µm |

120 V/µm |

120 V/µm |

120 V/µm |

120 V/µm |

120 V/µm |

120 V/µm |

120 V/µm |

|

Calculation method of break voltage [view]

|

|

|

|

|

|

|

|

|

| Pinholes acc. to IEC 60851-5 7 |

|

|

|

|

|

|

|

|

| 0.05mm: with 0% elongation |

good |

good |

very good |

very good |

very good |

very good |

|

|

| 0.25mm: with 0% elongation |

good |

good |

very good |

very good |

very good |

very good |

|

|

| Mechanical values |

|

|

|

|

|

|

|

|

| Elongation for Grade 1B wire |

|

|

|

|

|

|

|

|

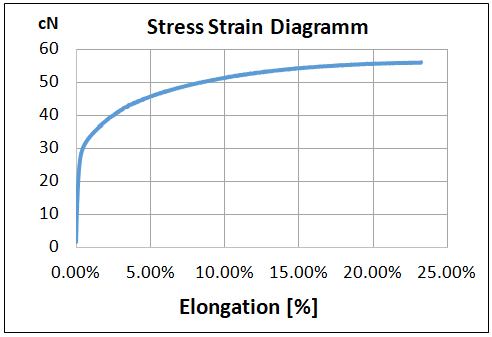

| 0.05mm: acc. to IEC 60851-3 3.1 |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

| Elektrisola typical value |

23% |

23% |

23% |

23% |

23% |

23% |

23% |

23% |

| 0.25mm: acc. to IEC 60851-3 3.1 |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

| Elektrisola typical value |

40% |

40% |

40% |

40% |

40% |

40% |

40% |

40% |

| Tensile strength for Grade 1B wires |

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

| 0.25mm: Elektrisola typical value |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

|

Stress strain chart [view]

|

|

|

|

|

|

|

|

|

| Bonding of wire |

|

|

|

|

|

|

|

|

| Hot air bonding |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.015 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.01 - 0.50 mm |

0.015 – 0.50 mm |

limited |

| Oven bonding |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 – 0.50 mm |

0.10 – 0.50 mm |

| Resistance bonding |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 - 0.50 mm |

0.10 – 0.50 mm |

0.10 – 0.50 mm |

| Solvent bonding |

limited |

suitable |

suitable |

suitable |

not suitable |

not suitable |

not suitable |

not suitable |

| Recommended solvent |

Ethanol / Methanol |

Ethanol / Methanol |

Ethanol / Methanol |

Ethanol / Methanol |

N/A |

N/A |

N/A |

N/A |

| Recommended bonding temperature |

120 - 140°C |

150 - 170°C |

150 - 170°C |

150 - 170°C |

150 - 170°C |

180 - 200°C |

200 – 220°C |

200 – 220°C |

Resoftening temperature for 0.25mm

(IEC 60851-3 7.1.2.4) |

≥ 100°C |

≥ 140°C |

≥ 170°C |

≥ 180°C |

≥ 180°C |

≥ 145°C |

≥ 190°C |

≥ 200°C |

| Bond strength chart |

|

|

|

|

|

|

|

|

| RoHS laboratory analysis |

view |

view |

view |

view |

|

view |

|

|

| Solderability |

|

|

|

|

|

|

|

|

| Solderability for Grade 1B wires |

|

|

|

|

|

|

|

|

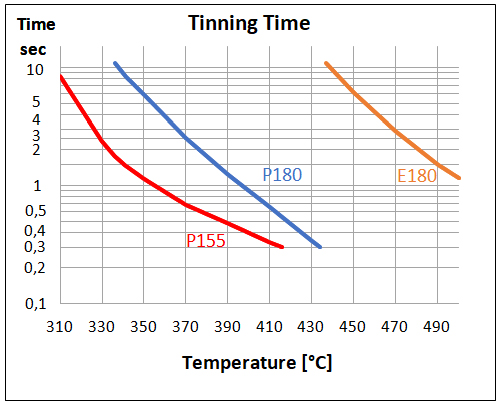

| 0.05mm: max. acc. to IEC 60851-4 5 |

2.0s / 390°C |

2.0s / 390°C |

2.0s / 390°C |

3.0s / 470°C |

2.0s / 390°C |

3.0s / 390°C |

3.0s / 390°C |

--- |

| Elektrisola typical value |

0.8s / 390°C |

0.4s / 390°C |

0.7s / 390°C |

1.3s / 470°C |

0.4s / 390°C |

0.4s / 420°C |

1.0s / 390°C |

--- |

| Elektrisola typical value |

1.5s / 370°C |

0.5s / 370°C |

1.0s / 370°C |

|

0.7s / 370°C |

--- |

|

|

| 0.25mm: max. acc. to IEC 60851-4 5 |

3.0s / 390°C |

3.0s / 390°C |

3.0s / 390°C |

3.0s / 470°C |

3.0s / 390°C |

3.0s / 390°C |

3.0s / 390°C |

--- |

| Elektrisola typical value |

1.4s / 390°C |

0.7s / 390°C |

1.6s / 390°C |

3.0s / 470°C |

0.7s / 390°C |

0.8s / 420°C |

2.0s / 390°C |

--- |

| Elektrisola typical value |

2.0s / 370°C |

1.2s / 370°C |

2.8s / 370°C |

|

1.2s / 370°C |

|

|

|

|

Solderability of different wire types chart [view]

|

|

|

|

|

|

|

|

|