| Product-Name |

Polysol© 155 |

Polysol-N© 155 |

Polysol© 155p |

Polysol© 180 |

Estersol© 180 |

Amidester© 200 |

Amidester© 210 |

|

|

| General Description |

mod. Polyurethane |

mod. Polyurethane/ Polyamide overcoat |

mod. Polyurethane |

mod. Polyurethane |

Polyesterimide |

Theic-mod. Polyesterimide |

A200 + Polyamidimide |

Polyamidimide |

aromatic Polyimide |

| IEC (including the following norms) |

IEC 60317-20, IEC 60317-4 |

IEC 60317-21, IEC 60317-19 |

IEC 60317-20, IEC 60317-4 |

IEC 60317-51, IEC 60317-20 |

IEC 60317-23, IEC 60317-3, IEC 60317-8 |

IEC 60317-84,

IEC 60317-8 |

IEC 60317-13 |

IEC 60317-57, IEC 60317-26 |

IEC 60317-46, IEC 60317-7 |

| NEMA (including the following norms) |

MW 79, MW 2, MW 75 |

MW 80, MW 28 |

MW 79, MW 2, MW 75 |

MW 82, MW 79, MW 75 |

MW 77, MW 5, MW 30 |

MW 74, MW 5, MW 30 |

MW 35, MW 73 |

MW 81 |

MW 16 |

| UL-approval |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

yes |

| Diameters available |

0.010 - 0.50 mm |

0.010 - 0.50 mm |

0.010 - 0.50 mm |

0.010 - 0.50 mm |

0.010 - 0.50 mm |

0.010 - 0.50 mm |

0.015 - 0.50 mm |

0.020 - 0.50 mm |

0.015 - 0.50 mm, ex USA |

| Properties |

Very good solderability and high thermal properties. |

Very good solderability with high thermal properties. |

Very good solderability and high thermal properties, no elongation pinholes. |

Good solderability at 370°C and elevated thermal values. |

Solderable at high temperatures, high thermal properties and good chemical resistance. |

Very high thermal properties and good chemical resistance. |

Very high thermal properties and high mechanical resistance. |

High thermal properties, good chemical resistance. |

Excellent thermal properties, excellent chemical and high radiation resistance. |

| Applications |

Small transformers, relays, solenoids, small motors, watch coils, transformers, instruments. |

Appliance motors, encapsulated coils, solenoids, transformers, toroids. |

Small transformers, timers, relays, small motors, solenoids, clock coils, watch coils, magnetic heads. |

Automotive coils as relays and ignition coils, transformers and solenoids. |

Small motors, small transformers, automotive coils. |

Motors, small motors, transformers. |

Motors, transformers. |

Small motors, automotive sensors and solenoids, transformers. |

Extreme loads and space applications. |

| Thermal values |

|

|

|

|

|

|

|

|

|

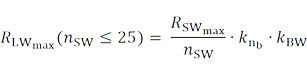

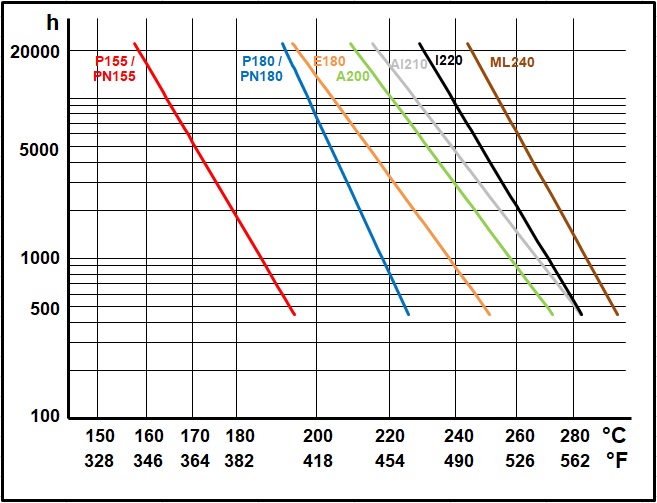

| Temperature index 20.000 h acc. to IEC 60172 |

158°C |

158°C |

164°C |

192°C |

195°C |

210°C |

212°C |

230°C |

245°C |

|

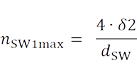

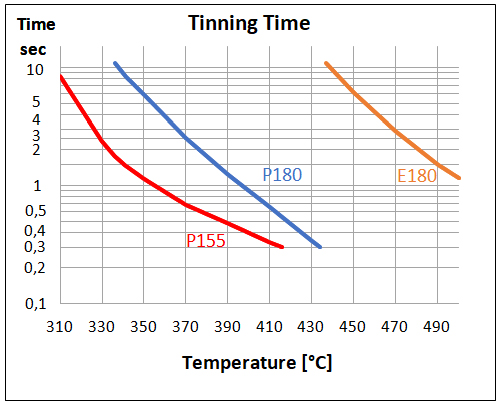

Thermal stability chart [view]

|

|

|

|

|

|

|

|

|

|

| Cut through temperature |

|

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-6 4 |

≥ 200°C |

≥ 200°C |

≥ 200°C |

≥ 230°C |

≥ 265°C |

≥ 320°C |

≥ 320°C |

≥ 350°C |

≥ 450°C |

| Elektrisola typical value |

225°C |

225°C |

225°C |

260°C |

315°C |

350°C |

365°C |

390°C |

450°C |

| 0.25mm: acc. to IEC 60851-6 4 |

≥ 200°C |

≥ 200°C |

≥ 200°C |

≥ 230°C |

≥ 265°C |

≥ 320°C |

|

≥ 350°C |

≥ 450°C |

| Elektrisola typical value |

230°C |

230°C |

230°C |

265°C |

325°C |

360°C |

380°C |

410°C |

450°C |

| Heat Shock |

|

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-6 3 |

≥ 175°C |

≥ 175°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 220°C |

≥ 220°C |

≥ 240°C |

≥ 260°C |

| Elektrisola typical value |

190°C |

190°C |

190°C |

210°C |

260°C |

230°C |

250°C |

250°C |

300°C |

| 0.25mm: acc. to IEC 60851-6 3 |

≥ 175°C |

≥ 175°C |

≥ 175°C |

≥ 200°C |

≥ 200°C |

≥ 220°C |

≥ 220°C |

≥ 240°C |

≥ 260°C |

| Elektrisola typical value |

180°C |

180°C |

180°C |

200°C |

250°C |

220°C |

240°C |

240°C |

300°C |

| Electrical values |

|

|

|

|

|

|

|

|

|

| Low voltage continuity for Grade 1 wires |

|

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-5 1 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

≤ 40 |

| Elektrisola typical value |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| High voltage continuity for Grade 1 wires |

|

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| 0.25mm: acc. to IEC 60851-5 2 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

≤ 10 |

| Elektrisola typical value |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| Pinholes acc. to JIS C3003.6c |

|

|

|

|

|

|

|

|

|

| with 0% elongation |

good |

good |

very good |

very good |

very good |

very good |

very good |

very good |

very good |

| with 3% elongation |

not good |

not good |

very good |

very good |

very good |

good |

very good |

very good |

very good |

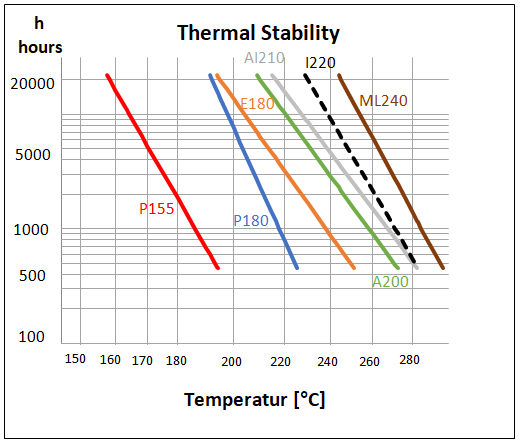

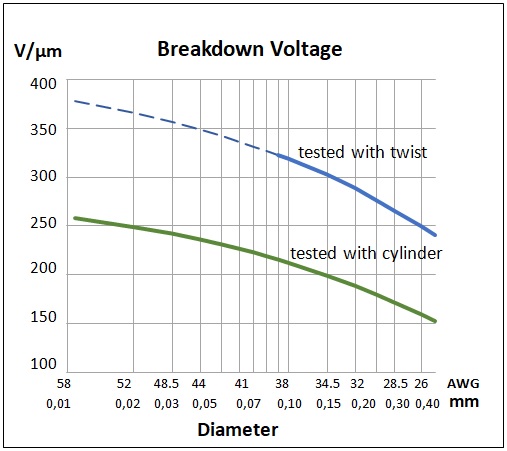

| Breakdown voltage acc. to IEC 60851-5 4 (at 20 ?, 35% humidity) |

|

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

220 V/µm |

210 V/µm |

220 V/µm |

220 V/µm |

220 V/µm |

220 V/µm |

210 V/µm |

210 V/µm |

210 V/µm |

| 0.25mm: Elektrisola typical value |

180 V/µm |

150 V/µm |

180 V/µm |

180 V/µm |

180 V/µm |

180 V/µm |

170 V/µm |

170 V/µm |

170 V/µm |

| Decrease of breakdown voltage for Grade 1 wires |

|

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

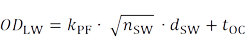

25% / 155°C |

30% / 155°C |

|

20% / 180°C |

20% / 180°C |

20% / 200°C |

20% / 205°C |

20% / 205°C |

15% / 220°C |

| 0.25mm: Elektrisola typical value |

25% / 155°C |

30% / 155°C |

25% / 155°C |

20% / 180°C |

20% / 180°C |

20% / 200°C |

20% / 205°C |

20% / 205°C |

15% / 220°C |

|

Calculation method of break voltage [view]

|

|

|

|

|

|

|

|

|

|

| Mechanical values |

|

|

|

|

|

|

|

|

|

| Elongation for Grade 1 wire |

|

|

|

|

|

|

|

|

|

| 0.05mm: acc. to IEC 60851-3 Part 3 1 |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

≥ 14% |

| Elektrisola typical value |

23% |

23% |

23% |

23% |

23% |

23% |

23% |

23% |

23% |

| 0.25mm: acc. to IEC 60851-3 Part 3 1 |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

≥ 25% |

| Elektrisola typical value |

40% |

40% |

40% |

40% |

40% |

40% |

40% |

40% |

40% |

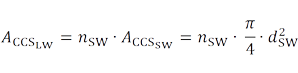

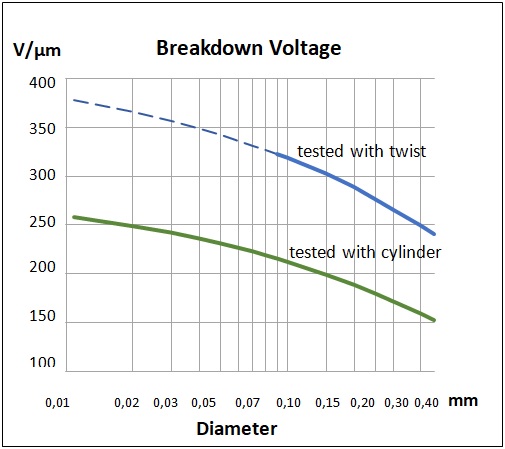

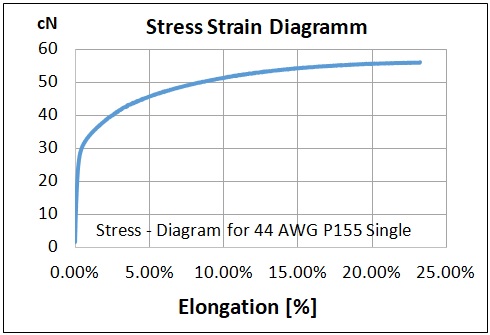

| Tensile strength for Grade 1 wires |

|

|

|

|

|

|

|

|

|

| 0.05mm: Elektrisola typical value |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

57 cN |

| 0.25mm: Elektrisola typical value |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

1370 cN |

|

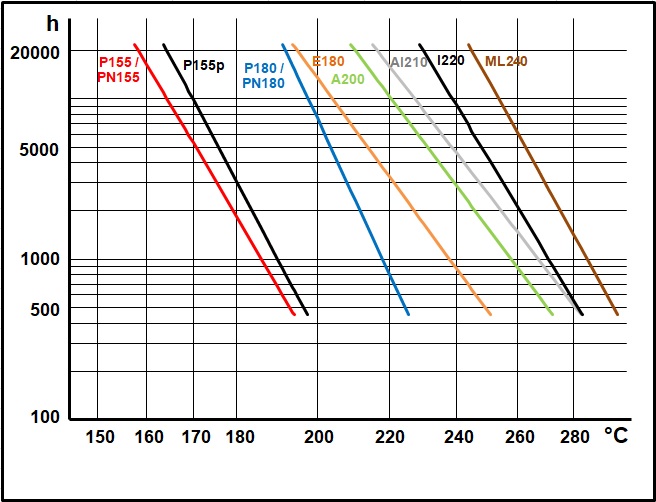

Stress strain chart [view]

|

|

|

|

|

|

|

|

|

|

| Chemical compatibility |

|

|

|

|

|

|

|

|

|

| Compatibility to standard solution |

|

|

|

|

|

|

|

|

|

| Pencil Hardness acc. to IEC 60851-4 3 with treatment |

4H |

4H |

4H |

4H |

4H |

4H |

4H |

4H |

6H |

| Pencil Hardness acc. to IEC 60851-4 3 without treatment |

4H |

4H |

4H |

4H |

4H |

4H |

4H |

4H |

6H |

| Decrease of breakdown voltage in % after treatment |

5% |

5% |

5% |

0% |

0% |

5% |

0% |

5% |

0% |

| RoHS laboratory analysis |

view |

view |

view |

view |

view |

view |

view |

|

|

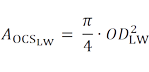

| Solderability |

|

|

|

|

|

|

|

|

|

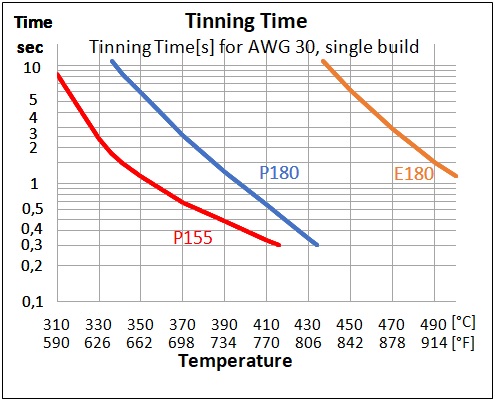

| Solderability for Grade 1 wires |

|

|

|

|

|

|

|

|

|

| 0.05mm: max. acc. to IEC 60851-4 5 |

2.0s / 390°C |

2.0s / 390°C |

2.0s / 390°C |

3.0s / 390°C |

3.0s / 470°C |

not solderable |

not solderable |

not solderable |

not solderable |

| Elektrisola typical value |

0.3s / 370°C |

0.3s / 370°C |

0.3s / 370°C |

1.8s / 370°C |

1.8s / 470°C |

|

|

|

|

| Elektrisola typical value |

0.2s / 390°C |

0.2s / 390°C |

0.2s / 390°C |

0.7s / 390°C |

|

|

|

|

|

| 0.25mm: max. acc. to IEC 60851-4 5 |

2.0s / 390°C |

2.0s / 390°C |

2.0s / 390°C |

3.0s / 390°C |

3.0s / 470°C |

not solderable |

not solderable |

not solderable |

not solderable |

| Elektrisola typical value |

0.7s / 370°C |

0.7s / 370°C |

0.7s / 370°C |

2.8s / 370°C |

2.8s / 470°C |

|

|

|

|

| Elektrisola typical value |

0.5s / 390°C |

0.5s / 390°C |

0.5s / 390°C |

1.1s / 390°C |

|

|

|

|

|

|

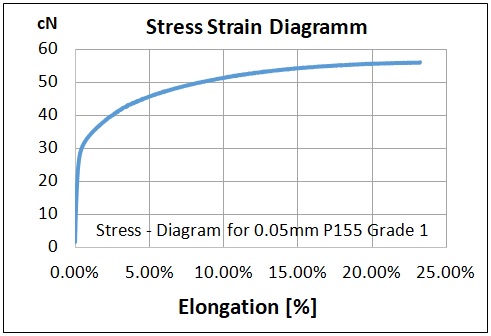

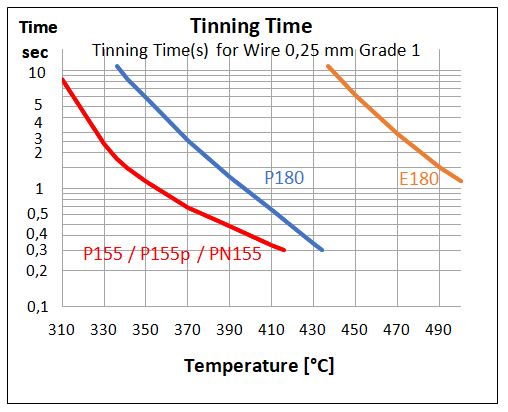

Solderability of different wire types chart [view]

|

|

|

|

|

|

|

|

|

|

Production,

Production,

Warehouse,

Warehouse,

Sales Office

Sales Office