LW Dimensions

Technical Data by Dimensions

| Nominal Diameter |

No of strands |

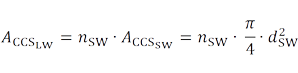

Cross section of conductor |

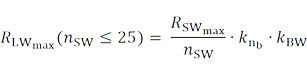

Resistance at 20 °C |

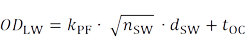

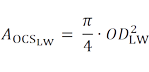

Outer diameter unserved |

Outer diameter single served |

Outer diameter double served |

1 kg HF-Litzwire unserved | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade 1 | Grade 2 | Grade 1 | Grade 2 | Grade 1 | Grade 2 | Grade 1 | Grade 2 | ||||||||||||

| nom | min | max | min | max | min | max | min | max | min | max | min | max | min | max | Length | Length | |||

| [mm] | # | [mm²] | [Ohm/m] | [Ohm/m] | [Ohm/m] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [m/kg] | [m/kg] |

| 0.020 | 10 | 0.0031 | 5.5500 | 4.9950 | 6.1050 | 0.087 | 0.095 | 0.099 | 0.107 | 0.112 | 0.135 | 0.124 | 0.147 | 0.137 | 0.175 | 0.149 | 0.187 | 33,344.48 | 31,689.48 |

| 0.020 | 12 | 0.0038 | 4.6550 | 4.1625 | 5.0875 | 0.095 | 0.104 | 0.108 | 0.177 | 0.120 | 0.144 | 0.133 | 0.157 | 0.145 | 0.184 | 0.158 | 0.197 | 22,787.07 | 26,407.90 |

| 0.020 | 16 | 0.0050 | 3.4688 | 3.1219 | 3.8156 | 0.111 | 0.121 | 0.126 | 0.138 | 0.136 | 0.161 | 0.151 | 0.176 | 0.163 | 0.201 | 0.176 | 0.216 | 20,840.30 | 19,805.93 |

| 0.020 | 20 | 0.0063 | 2.7750 | 2.4975 | 3.0525 | 0.125 | 0.136 | 0.142 | 0.153 | 0.150 | 0.176 | 0.176 | 0.193 | 0.175 | 0.216 | 0.192 | 0.233 | 16,672.24 | 15,844.74 |

| 0.020 | 30 | 0.0094 | 1.8500 | 1.6650 | 2.0350 | 0.154 | 0.168 | 0.175 | 0.189 | 0.179 | 0.208 | 0.200 | 0.229 | 0.204 | 0.248 | 0.225 | 0.269 | 11,114.83 | 10,583.16 |

| 0.020 | 60 | 0.0188 | 0.9434 | 0.8488 | 1.0375 | 0.218 | 0.238 | 0.248 | 0.268 | 0.243 | 0.278 | 0.273 | 0.308 | 0.268 | 0.318 | 0.298 | 0.348 | 5557.41 | 5281.58 |

| 0.020 | 120 | 0.0377 | 0.4716 | 0.4244 | 0.5187 | 0.308 | 0.337 | 0.351 | 0.379 | 0.333 | 0.377 | 0.376 | 0.419 | 0.358 | 0.417 | 0.401 | 0.459 | 2778.71 | 2640.79 |

| 0.020 | 180 | 0.0565 | 0.3204 | 0.2884 | 0.3525 | 0.378 | 0.412 | 0.429 | 0.464 | 0.403 | 0.452 | 0.454 | 0.504 | 0.428 | 0.492 | 0.479 | 0.544 | 1852.47 | 1760.53 |

| 0.020 | 200 | 0.0628 | 0.2829 | 0.2546 | 0.3112 | 0.398 | 0.434 | 0.453 | 0.489 | 0.423 | 0.474 | 0.478 | 0.529 | 0.448 | 0.514 | 0.503 | 0.569 | 1667.22 | 1584.47 |

| 0.020 | 270 | 0.0848 | 0.2136 | 0.1923 | 0.2350 | 0.463 | 0.505 | 0.526 | 0.568 | 0.488 | 0.545 | 0.551 | 0.608 | 0.513 | 0.585 | 0.576 | 0.648 | 1234.98 | 1173.68 |

| 0.020 | 600 | 0.1885 | 0.0961 | 0.0865 | 0.1057 | 0.690 | 0.752 | 0.784 | 0.847 | 0.715 | 0.792 | 0.809 | 0.887 | 0.740 | 0.832 | 0.834 | 0.927 | 555.74 | 528.16 |

| 0.020 | 800 | 0.2513 | 0.0721 | 0.0649 | 0.0793 | 0.796 | 0.869 | 0.905 | 0.978 | 0.821 | 0.909 | 0.930 | 1.018 | 0.846 | 0.949 | 0.955 | 1.058 | 416.81 | 396.12 |

| 0.020 | 1000 | 0.3142 | 0.0577 | 0.0519 | 0.0634 | 0.890 | 0.971 | 1.012 | 1.093 | 0.915 | 1.011 | 1.037 | 1.133 | 0.940 | 1.051 | 1.062 | 1.173 | 333.44 | 316.89 |

| 0.030 | 10 | 0.0071 | 2.4667 | 2.2200 | 2.7133 | 0.130 | 0.146 | 0.150 | 0.162 | 0.155 | 0.186 | 0.175 | 0.202 | 0.180 | 0.226 | 0.200 | 0.242 | 14,738.90 | 14,001.74 |

| 0.030 | 12 | 0.0085 | 2.0556 | 1.8500 | 2.2611 | 0.143 | 0.160 | 0.165 | 0.178 | 0.168 | 0.200 | 0.190 | 0.218 | 0.193 | 0.240 | 0.215 | 0.258 | 12,282.41 | 11,668.12 |

| 0.030 | 16 | 0.0113 | 1.5417 | 1.3875 | 1.6958 | 0.168 | 0.186 | 0.192 | 0.207 | 0.191 | 0.226 | 0.217 | 0.247 | 0.216 | 0.266 | 0.242 | 0.287 | 9211.81 | 8751.09 |

| 0.030 | 20 | 0.0141 | 1.2333 | 1.1100 | 1.3567 | 0.187 | 0.210 | 0.216 | 0.233 | 0.212 | 0.250 | 0.241 | 0.273 | 0.237 | 0.290 | 0.266 | 0.313 | 7369.45 | 7000.87 |

| 0.030 | 30 | 0.0212 | 0.8222 | 0.7400 | 0.9044 | 0.231 | 0.259 | 0.266 | 0.287 | 0.256 | 0.299 | 0.291 | 0.327 | 0.281 | 0.339 | 0.316 | 0.367 | 4912.97 | 4667.25 |

| 0.030 | 60 | 0.0424 | 0.4192 | 0.3773 | 0.4611 | 0.327 | 0.367 | 0.377 | 0.407 | 0.352 | 0.407 | 0.402 | 0.447 | 0.377 | 0.447 | 0.427 | 0.487 | 2456.48 | 2333.62 |

| 0.030 | 90 | 0.0636 | 0.2794 | 0.2515 | 0.3074 | 0.401 | 0.449 | 0.461 | 0.498 | 0.426 | 0.489 | 0.486 | 0.538 | 0.451 | 0.529 | 0.511 | 0.578 | 1637.66 | 1555.75 |

| 0.030 | 120 | 0.0848 | 0.2096 | 0.1886 | 0.2305 | 0.463 | 0.519 | 0.533 | 0.575 | 0.488 | 0.559 | 0.558 | 0.615 | 0.513 | 0.599 | 0.583 | 0.655 | 1228.24 | 1166.81 |

| 0.030 | 180 | 0.1272 | 0.1424 | 0.1282 | 0.1567 | 0.567 | 0.635 | 0.653 | 0.704 | 0.592 | 0.675 | 0.678 | 0.744 | 0.617 | 0.715 | 0.703 | 0.784 | 818.83 | 777.87 |

| 0.030 | 200 | 0.1414 | 0.1258 | 0.1132 | 0.1383 | 0.597 | 0.670 | 0.688 | 0.742 | 0.622 | 0.710 | 0.713 | 0.782 | 0.647 | 0.750 | 0.738 | 0.822 | 736.94 | 700.09 |

| 0.030 | 270 | 0.1909 | 0.0949 | 0.0854 | 0.1044 | 0.694 | 0.778 | 0.799 | 0.862 | 0.719 | 0.818 | 0.824 | 0.902 | 0.744 | 0.858 | 0.849 | 0.942 | 545.89 | 518.58 |

| 0.030 | 600 | 0.4241 | 0.0427 | 0.0385 | 0.0470 | 1.035 | 1.160 | 1.191 | 1.285 | 1.060 | 1.200 | 1.216 | 1.325 | 1.085 | 1.240 | 1.241 | 1.365 | 245.65 | 233.36 |

| 0.030 | 800 | 0.5655 | 0.0320 | 0.0288 | 0.0352 | 1.195 | 1.340 | 1.376 | 1.484 | 1.220 | 1.380 | 1.401 | 1.524 | 1.245 | 1.420 | 1.426 | 1.564 | 184.24 | 175.02 |

| 0.030 | 1000 | 0.7069 | 0.0256 | 0.0231 | 0.0282 | 1.336 | 1.498 | 1.538 | 1.660 | 1.361 | 1.538 | 1.563 | 1.700 | 1.386 | 1.578 | 1.588 | 1.740 | 147.39 | 140.02 |

| 0.040 | 4 | 0.0050 | 3.4688 | 3.1322 | 3.8051 | 0.110 | 0.123 | 0.125 | 0.135 | 0.135 | 0.163 | 0.150 | 0.175 | 0.160 | 0.203 | 0.175 | 0.215 | 20,755.04 | 19,805.93 |

| 0.040 | 8 | 0.0101 | 1.7344 | 1.5661 | 1.9026 | 0.156 | 0.173 | 0.177 | 0.191 | 0.181 | 0.213 | 0.202 | 0.231 | 0.206 | 0.253 | 0.227 | 0.271 | 10,377.52 | 9902.96 |

| 0.040 | 10 | 0.0126 | 1.3875 | 1.2529 | 1.5220 | 0.174 | 0.194 | 0.198 | 0.213 | 0.199 | 0.234 | 0.223 | 0.253 | 0.224 | 0.274 | 0.248 | 0.293 | 8302.02 | 7922.37 |

| 0.040 | 15 | 0.0188 | 0.9250 | 0.8352 | 1.0147 | 0.215 | 0.239 | 0.244 | 0.264 | 0.240 | 0.279 | 0.269 | 0.304 | 0.265 | 0.319 | 0.294 | 0.344 | 5534.68 | 5281.58 |

| 0.040 | 20 | 0.0251 | 0.6938 | 0.6264 | 0.7610 | 0.250 | 0.279 | 0.284 | 0.307 | 0.275 | 0.318 | 0.309 | 0.347 | 0.300 | 0.358 | 0.334 | 0.387 | 4151.01 | 3961.19 |

| 0.040 | 25 | 0.0314 | 0.5550 | 0.5011 | 0.6088 | 0.282 | 0.314 | 0.320 | 0.346 | 0.307 | 0.354 | 0.345 | 0.386 | 0.332 | 0.394 | 0.370 | 0.426 | 3320.81 | 3168.95 |

| 0.040 | 30 | 0.0377 | 0.4625 | 0.4176 | 0.5073 | 0.308 | 0.344 | 0.351 | 0.379 | 0.333 | 0.384 | 0.376 | 0.419 | 0.358 | 0.424 | 0.401 | 0.459 | 2767.34 | 2640.79 |

| 0.040 | 35 | 0.0440 | 0.3964 | 0.3580 | 0.4349 | 0.333 | 0.371 | 0.379 | 0.409 | 0.358 | 0.411 | 0.404 | 0.449 | 0.383 | 0.451 | 0.429 | 0.489 | 2372.00 | 2263.53 |

| 0.040 | 45 | 0.0565 | 0.3083 | 0.2784 | 0.3382 | 0.378 | 0.421 | 0.429 | 0.464 | 0.403 | 0.461 | 0.454 | 0.504 | 0.428 | 0.501 | 0.479 | 0.544 | 1844.89 | 1760.53 |

| 0.040 | 60 | 0.0754 | 0.2358 | 0.2129 | 0.2586 | 0.436 | 0.486 | 0.496 | 0.535 | 0.461 | 0.526 | 0.521 | 0.575 | 0.486 | 0.566 | 0.546 | 0.615 | 1383.67 | 1320.40 |

| 0.040 | 75 | 0.0942 | 0.1886 | 0.1703 | 0.2069 | 0.488 | 0.543 | 0.554 | 0.599 | 0.513 | 0.583 | 0.579 | 0.639 | 0.538 | 0.623 | 0.604 | 0.679 | 1106.94 | 1056.32 |

| 0.040 | 90 | 0.1131 | 0.1572 | 0.1419 | 0.1724 | 0.534 | 0.595 | 0.607 | 0.656 | 0.559 | 0.635 | 0.632 | 0.696 | 0.584 | 0.675 | 0.657 | 0.736 | 922.45 | 880.26 |

| 0.040 | 105 | 0.1319 | 0.1347 | 0.1217 | 0.1478 | 0.577 | 0.643 | 0.656 | 0.708 | 0.602 | 0.683 | 0.681 | 0.748 | 0.627 | 0.723 | 0.706 | 0.788 | 790.67 | 754.51 |

| 0.040 | 180 | 0.2262 | 0.0801 | 0.0723 | 0.0879 | 0.756 | 0.841 | 0.859 | 0.927 | 0.781 | 0.881 | 0.884 | 0.967 | 0.806 | 0.921 | 0.909 | 1.007 | 461.22 | 440.13 |

| 0.040 | 225 | 0.2827 | 0.0641 | 0.0579 | 0.0703 | 0.845 | 0.941 | 0.960 | 1.037 | 0.870 | 0.981 | 0.985 | 1.077 | 0.895 | 1.021 | 1.010 | 1.117 | 368.98 | 352.11 |

| 0.040 | 270 | 0.3393 | 0.0534 | 0.0482 | 0.0586 | 0.925 | 1.031 | 1.052 | 1.136 | 0.950 | 1.071 | 1.077 | 1.176 | 0.975 | 1.111 | 1.102 | 1.216 | 307.48 | 293.42 |

| 0.040 | 600 | 0.7540 | 0.0240 | 0.0217 | 0.0264 | 1.380 | 1.536 | 1.568 | 1.693 | 1.405 | 1.576 | 1.593 | 1.733 | 1.430 | 1.616 | 1.618 | 1.773 | 138.37 | 132.04 |

| 0.040 | 800 | 1.0053 | 0.0180 | 0.0163 | 0.0198 | 1.593 | 1.774 | 1.810 | 1.955 | 1.618 | 1.814 | 1.835 | 1.995 | 1.643 | 1.854 | 1.860 | 2.035 | 103.78 | 99.03 |

| 0.040 | 1000 | 1.2566 | 0.0144 | 0.0130 | 0.0158 | 1.781 | 1.983 | 2.024 | 2.186 | 1.806 | 2.023 | 2.049 | 2.226 | 1.831 | 2.063 | 2.074 | 2.266 | 83.02 | 79.22 |

| 0.050 | 4 | 0.0079 | 2.2200 | 2.0202 | 2.4198 | 0.138 | 0.150 | 0.153 | 0.165 | 0.163 | 0.190 | 0.178 | 0.205 | 0.188 | 0.230 | 0.203 | 0.245 | 13,337.79 | 12,809.17 |

| 0.050 | 8 | 0.0157 | 1.1100 | 1.0101 | 1.2099 | 0.194 | 0.212 | 0.216 | 0.233 | 0.219 | 0.252 | 0.241 | 0.273 | 0.244 | 0.292 | 0.266 | 0.313 | 6668.90 | 6404.59 |

| 0.050 | 10 | 0.0196 | 0.8880 | 0.8081 | 0.9679 | 0.217 | 0.237 | 0.241 | 0.261 | 0.242 | 0.277 | 0.266 | 0.301 | 0.267 | 0.317 | 0.291 | 0.341 | 5335.12 | 5123.67 |

| 0.050 | 15 | 0.0295 | 0.5920 | 0.5387 | 0.6453 | 0.268 | 0.293 | 0.298 | 0.322 | 0.293 | 0.333 | 0.323 | 0.362 | 0.318 | 0.373 | 0.348 | 0.402 | 3556.74 | 3415.78 |

| 0.050 | 20 | 0.0393 | 0.4440 | 0.4040 | 0.4840 | 0.312 | 0.341 | 0.346 | 0.375 | 0.337 | 0.381 | 0.371 | 0.415 | 0.362 | 0.421 | 0.396 | 0.455 | 2667.56 | 2561.83 |

| 0.050 | 25 | 0.0491 | 0.3552 | 0.3232 | 0.3872 | 0.352 | 0.384 | 0.390 | 0.422 | 0.377 | 0.424 | 0.415 | 0.462 | 0.402 | 0.464 | 0.440 | 0.502 | 2134.05 | 2049.47 |

| 0.050 | 30 | 0.0589 | 0.2960 | 0.2694 | 0.3226 | 0.386 | 0.421 | 0.428 | 0.463 | 0.411 | 0.461 | 0.453 | 0.503 | 0.436 | 0.501 | 0.478 | 0.543 | 1778.37 | 1707.89 |

| 0.050 | 35 | 0.0687 | 0.2537 | 0.2309 | 0.2765 | 0.416 | 0.454 | 0.462 | 0.500 | 0.441 | 0.494 | 0.487 | 0.540 | 0.466 | 0.534 | 0.512 | 0.580 | 1524.32 | 1463.91 |

| 0.050 | 45 | 0.0884 | 0.1973 | 0.1796 | 0.2151 | 0.472 | 0.515 | 0.524 | 0.567 | 0.497 | 0.555 | 0.549 | 0.607 | 0.522 | 0.595 | 0.574 | 0.647 | 1185.58 | 1138.59 |

| 0.050 | 60 | 0.1178 | 0.1509 | 0.1373 | 0.1645 | 0.545 | 0.595 | 0.605 | 0.654 | 0.570 | 0.635 | 0.630 | 0.694 | 0.595 | 0.675 | 0.655 | 0.734 | 889.19 | 853.94 |

| 0.050 | 75 | 0.1473 | 0.1207 | 0.1099 | 0.1316 | 0.610 | 0.665 | 0.676 | 0.732 | 0.635 | 0.705 | 0.701 | 0.772 | 0.660 | 0.745 | 0.726 | 0.812 | 711.35 | 683.16 |

| 0.050 | 90 | 0.1767 | 0.1006 | 0.0915 | 0.1097 | 0.668 | 0.729 | 0.741 | 0.801 | 0.693 | 0.769 | 0.766 | 0.841 | 0.718 | 0.809 | 0.791 | 0.881 | 592.79 | 569.30 |

| 0.050 | 105 | 0.2062 | 0.0862 | 0.0785 | 0.0940 | 0.721 | 0.787 | 0.800 | 0.866 | 0.746 | 0.827 | 0.825 | 0.906 | 0.771 | 0.867 | 0.850 | 0.946 | 508.11 | 487.97 |

| 0.050 | 180 | 0.3534 | 0.0513 | 0.0467 | 0.0559 | 0.945 | 1.030 | 1.048 | 1.133 | 0.970 | 1.070 | 1.073 | 1.173 | 0.995 | 1.110 | 1.098 | 1.213 | 296.40 | 284.65 |

| 0.050 | 225 | 0.4418 | 0.0410 | 0.0373 | 0.0447 | 1.056 | 1.152 | 1.171 | 1.267 | 1.081 | 1.192 | 1.196 | 1.307 | 1.106 | 1.232 | 1.221 | 1.347 | 237.12 | 227.72 |

| 0.050 | 270 | 0.5301 | 0.0342 | 0.0311 | 0.0373 | 1.157 | 1.262 | 1.283 | 1.388 | 1.182 | 1.302 | 1.308 | 1.428 | 1.207 | 1.342 | 1.333 | 1.468 | 197.60 | 189.77 |

| 0.050 | 600 | 1.1781 | 0.0154 | 0.0140 | 0.0168 | 1.724 | 1.881 | 1.913 | 2.069 | 1.749 | 1.921 | 1.938 | 2.109 | 1.774 | 1.961 | 1.963 | 2.149 | 88.92 | 85.39 |

| 0.050 | 800 | 1.5708 | 0.0115 | 0.0105 | 0.0126 | 1.991 | 2.172 | 2.208 | 2.389 | 2.016 | 2.212 | 2.233 | 2.429 | 2.041 | 2.252 | 2.258 | 2.469 | 66.69 | 64.05 |

| 0.050 | 1000 | 1.9635 | 0.0092 | 0.0084 | 0.0101 | 2.226 | 2.429 | 2.469 | 2.671 | 2.251 | 2.469 | 2.494 | 2.711 | 2.276 | 2.509 | 2.519 | 2.751 | 53.35 | 51.24 |

| 0.071 | 4 | 0.0158 | 1.1010 | 1.0049 | 1.2106 | 0.195 | 0.210 | 0.213 | 0.228 | 0.220 | 0.250 | 0.238 | 0.268 | 0.245 | 0.290 | 0.263 | 0.308 | 6634.43 | 6419.69 |

| 0.071 | 8 | 0.0317 | 0.5505 | 0.5025 | 0.6053 | 0.276 | 0.297 | 0.301 | 0.322 | 0.301 | 0.337 | 0.326 | 0.362 | 0.326 | 0.377 | 0.351 | 0.402 | 3317.21 | 3209.85 |

| 0.071 | 10 | 0.0396 | 0.4404 | 0.4020 | 0.4842 | 0.308 | 0.332 | 0.336 | 0.360 | 0.333 | 0.372 | 0.361 | 0.400 | 0.358 | 0.412 | 0.386 | 0.440 | 2653.77 | 2567.88 |

| 0.071 | 15 | 0.0594 | 0.2936 | 0.2680 | 0.3228 | 0.381 | 0.410 | 0.415 | 0.444 | 0.406 | 0.450 | 0.440 | 0.484 | 0.431 | 0.490 | 0.465 | 0.524 | 1769.18 | 1711.92 |

| 0.071 | 20 | 0.0792 | 0.2202 | 0.2010 | 0.2421 | 0.443 | 0.477 | 0.483 | 0.517 | 0.468 | 0.517 | 0.508 | 0.567 | 0.493 | 0.557 | 0.533 | 0.597 | 1326.89 | 1283.94 |

| 0.071 | 25 | 0.0990 | 0.1762 | 0.1608 | 0.1937 | 0.499 | 0.538 | 0.544 | 0.582 | 0.524 | 0.578 | 0.569 | 0.622 | 0.549 | 0.618 | 0.594 | 0.662 | 1061.51 | 1027.15 |

| 0.071 | 30 | 0.1188 | 0.1468 | 0.1340 | 0.1614 | 0.547 | 0.589 | 0.596 | 0.638 | 0.572 | 0.629 | 0.621 | 0.678 | 0.597 | 0.669 | 0.646 | 0.718 | 884.59 | 855.96 |

| 0.071 | 35 | 0.1386 | 0.1258 | 0.1148 | 0.1384 | 0.591 | 0.636 | 0.644 | 0.689 | 0.616 | 0.676 | 0.669 | 0.729 | 0.641 | 0.716 | 0.694 | 0.769 | 758.22 | 733.68 |

| 0.071 | 45 | 0.1782 | 0.0979 | 0.0893 | 0.1076 | 0.670 | 0.721 | 0.730 | 0.781 | 0.695 | 0.761 | 0.755 | 0.821 | 0.720 | 0.801 | 0.780 | 0.861 | 589.73 | 570.64 |

| 0.071 | 60 | 0.2376 | 0.0748 | 0.0683 | 0.0823 | 0.773 | 0.833 | 0.843 | 0.902 | 0.798 | 0.873 | 0.868 | 0.942 | 0.823 | 0.913 | 0.893 | 0.982 | 442.30 | 427.98 |

| 0.071 | 75 | 0.2969 | 0.0699 | 0.0546 | 0.0658 | 0.865 | 0.931 | 0.942 | 1.009 | 0.890 | 0.971 | 0.967 | 1.049 | 0.915 | 1.011 | 0.992 | 1.089 | 353.84 | 342.38 |

| 0.071 | 90 | 0.3563 | 0.0499 | 0.0455 | 0.0549 | 0.947 | 1.020 | 1.032 | 1.105 | 0.972 | 1.060 | 1.057 | 1.145 | 0.997 | 1.100 | 1.082 | 1.185 | 294.86 | 285.32 |

| 0.071 | 105 | 0.4157 | 0.0428 | 0.0390 | 0.0470 | 1.023 | 1.102 | 1.115 | 1.194 | 1.048 | 1.142 | 1.140 | 1.234 | 1.073 | 1.182 | 1.165 | 1.274 | 252.74 | 244.56 |

| 0.071 | 135 | 0.5345 | 0.0333 | 0.0304 | 0.0366 | 1.160 | 1.249 | 1.264 | 1.353 | 1.185 | 1.289 | 1.289 | 1.393 | 1.210 | 1.329 | 1.314 | 1.433 | 196.58 | 190.21 |

| 0.071 | 180 | 0.7127 | 0.0254 | 0.0232 | 0.0280 | 1.339 | 1.443 | 1.460 | 1.563 | 1.364 | 1.483 | 1.485 | 1.603 | 1.389 | 1.523 | 1.510 | 1.643 | 147.43 | 142.66 |

| 0.071 | 225 | 0.8908 | 0.0203 | 0.0186 | 0.0224 | 1.498 | 1.613 | 1.632 | 1.747 | 1.523 | 1.653 | 1.657 | 1.787 | 1.548 | 1.693 | 1.682 | 1.827 | 117.95 | 114.13 |

| 0.071 | 270 | 1.0690 | 0.0170 | 0.0155 | 0.0186 | 1.641 | 1.767 | 1.788 | 1.914 | 1.666 | 1.807 | 1.813 | 1.954 | 1.691 | 1.847 | 1.838 | 1.994 | 98.29 | 95.11 |

| 0.071 | 600 | 2.3755 | 0.0076 | 0.0070 | 0.0084 | 2.446 | 2.634 | 2.665 | 2.853 | 2.471 | 2.674 | 2.690 | 2.893 | 2.496 | 2.714 | 2.715 | 2.933 | 44.23 | 42.80 |

| 0.071 | 800 | 3.1674 | 0.0057 | 0.0052 | 0.0063 | 2.824 | 3.041 | 3.077 | 3.295 | 2.849 | 3.081 | 3.102 | 3.335 | 2.874 | 3.121 | 3.127 | 3.375 | 33.17 | 32.10 |

| 0.071 | 1000 | 3.9592 | 0.0046 | 0.0042 | 0.0050 | 3.157 | 3.400 | 3.441 | 3.683 | 3.182 | 3.440 | 3.466 | 3.723 | 3.207 | 3.480 | 3.491 | 3.763 | 26.54 | 25.68 |

| 0.080 | 4 | 0.0201 | 0.8672 | 0.7988 | 0.9441 | 0.218 | 0.235 | 0.238 | 0.253 | 0.243 | 0.275 | 0.263 | 0.293 | 0.268 | 0.315 | 0.288 | 0.333 | 5241.94 | 5081.45 |

| 0.080 | 8 | 0.0402 | 0.4336 | 0.3994 | 0.4721 | 0.308 | 0.332 | 0.336 | 0.357 | 0.333 | 0.372 | 0.361 | 0.397 | 0.358 | 0.412 | 0.386 | 0.437 | 2620.97 | 2540.72 |

| 0.080 | 10 | 0.0503 | 0.3469 | 0.3195 | 0.3777 | 0.344 | 0.372 | 0.376 | 0.399 | 0.369 | 0.412 | 0.401 | 0.439 | 0.394 | 0.452 | 0.426 | 0.479 | 2096.78 | 2032.58 |

| 0.080 | 15 | 0.0754 | 0.2312 | 0.2130 | 0.2518 | 0.425 | 0.459 | 0.464 | 0.493 | 0.450 | 0.499 | 0.489 | 0.533 | 0.475 | 0.539 | 0.514 | 0.573 | 1397.85 | 1355.05 |

| 0.080 | 20 | 0.1005 | 0.1734 | 0.1598 | 0.1888 | 0.494 | 0.534 | 0.540 | 0.574 | 0.519 | 0.574 | 0.565 | 0.614 | 0.544 | 0.614 | 0.590 | 0.654 | 1048.39 | 1016.29 |

| 0.080 | 25 | 0.1257 | 0.1387 | 0.1278 | 0.1511 | 0.557 | 0.602 | 0.608 | 0.646 | 0.582 | 0.642 | 0.633 | 0.686 | 0.607 | 0.682 | 0.658 | 0.726 | 838.71 | 813.03 |

| 0.080 | 30 | 0.1508 | 0.1156 | 0.1065 | 0.1259 | 0.610 | 0.659 | 0.666 | 0.708 | 0.635 | 0.699 | 0.691 | 0.748 | 0.660 | 0.739 | 0.716 | 0.788 | 698.93 | 677.53 |

| 0.080 | 35 | 0.1759 | 0.0991 | 0.0913 | 0.1079 | 0.659 | 0.712 | 0.719 | 0.765 | 0.684 | 0.752 | 0.744 | 0.805 | 0.709 | 0.792 | 0.769 | 0.845 | 599.08 | 580.74 |

| 0.080 | 45 | 0.2262 | 0.0771 | 0.0710 | 0.0839 | 0.747 | 0.807 | 0.816 | 0.867 | 0.772 | 0.847 | 0.841 | 0.907 | 0.797 | 0.887 | 0.866 | 0.947 | 465.95 | 451.68 |

| 0.080 | 60 | 0.3016 | 0.0589 | 0.0543 | 0.0642 | 0.863 | 0.932 | 0.942 | 1.001 | 0.888 | 0.972 | 0.967 | 1.041 | 0.913 | 1.012 | 0.992 | 1.081 | 349.46 | 338.78 |

| 0.080 | 75 | 0.3770 | 0.0472 | 0.0434 | 0.0513 | 0.964 | 1.042 | 1.053 | 1.120 | 0.989 | 1.082 | 1.078 | 1.160 | 1.014 | 1.122 | 1.103 | 1.200 | 279.57 | 271.01 |

| 0.080 | 90 | 0.4524 | 0.0393 | 0.0362 | 0.0428 | 1.056 | 1.141 | 1.154 | 1.226 | 1.081 | 1.181 | 1.179 | 1.266 | 1.106 | 1.221 | 1.204 | 1.306 | 232.98 | 225.84 |

| 0.080 | 105 | 0.5278 | 0.0337 | 0.0310 | 0.0367 | 1.141 | 1.233 | 1.246 | 1.325 | 1.166 | 1.273 | 1.271 | 1.365 | 1.191 | 1.313 | 1.296 | 1.405 | 199.69 | 193.58 |

| 0.080 | 180 | 0.9048 | 0.0200 | 0.0184 | 0.0218 | 1.494 | 1.614 | 1.631 | 1.734 | 1.519 | 1.654 | 1.656 | 1.774 | 1.544 | 1.694 | 1.681 | 1.814 | 116.49 | 112.92 |

| 0.080 | 225 | 1.1310 | 0.0160 | 0.0148 | 0.0174 | 1.670 | 1.805 | 1.824 | 1.939 | 1.695 | 1.845 | 1.849 | 1.979 | 1.720 | 1.885 | 1.874 | 2.019 | 93.19 | 90.34 |

| 0.080 | 270 | 1.3572 | 0.0134 | 0.0123 | 0.0145 | 1.830 | 1.977 | 1.998 | 2.124 | 1.855 | 2.017 | 2.023 | 2.164 | 1.880 | 2.057 | 2.048 | 2.204 | 77.66 | 75.28 |

| 0.080 | 600 | 3.0159 | 0.0060 | 0.0055 | 0.0065 | 2.728 | 2.947 | 2.979 | 3.167 | 2.753 | 2.987 | 3.004 | 3.207 | 2.778 | 3.027 | 3.029 | 3.247 | 34.95 | 33.88 |

| 0.080 | 800 | 4.0212 | 0.0045 | 0.0042 | 0.0049 | 3.150 | 3.403 | 3.439 | 3.657 | 3.175 | 3.443 | 3.464 | 3.697 | 3.200 | 3.483 | 3.489 | 3.737 | 26.21 | 25.41 |

| 0.080 | 1000 | 5.0265 | 0.0036 | 0.0033 | 0.0039 | 3.522 | 3.805 | 3.845 | 4.088 | 3.547 | 3.845 | 3.870 | 4.128 | 3.572 | 3.885 | 3.895 | 4.168 | 20.97 | 20.33 |

| 0.100 | 4 | 0.0314 | 0.5550 | 0.5187 | 0.5949 | 0.270 | 0.293 | 0.295 | 0.313 | 0.295 | 0.333 | 0.320 | 0.353 | 0.320 | 0.373 | 0.345 | 0.393 | 3361.62 | 3263.16 |

| 0.100 | 8 | 0.0628 | 0.2775 | 0.2594 | 0.2975 | 0.382 | 0.414 | 0.417 | 0.442 | 0.407 | 0.454 | 0.442 | 0.482 | 0.432 | 0.494 | 0.467 | 0.522 | 1680.81 | 1631.58 |

| 0.100 | 10 | 0.0785 | 0.2220 | 0.2075 | 0.2380 | 0.427 | 0.462 | 0.466 | 0.494 | 0.452 | 0.502 | 0.491 | 0.534 | 0.477 | 0.542 | 0.516 | 0.574 | 1344.65 | 1305.26 |

| 0.100 | 15 | 0.1178 | 0.1480 | 0.1383 | 0.1587 | 0.527 | 0.571 | 0.576 | 0.610 | 0.552 | 0.611 | 0.601 | 0.650 | 0.577 | 0.651 | 0.626 | 0.690 | 896.43 | 870.18 |

| 0.100 | 20 | 0.1571 | 0.1110 | 0.1037 | 0.1190 | 0.613 | 0.665 | 0.670 | 0.710 | 0.638 | 0.705 | 0.695 | 0.750 | 0.663 | 0.745 | 0.720 | 0.790 | 672.32 | 652.63 |

| 0.100 | 25 | 0.1963 | 0.0888 | 0.0830 | 0.0952 | 0.691 | 0.749 | 0.755 | 0.800 | 0.716 | 0.789 | 0.780 | 0.840 | 0.741 | 0.829 | 0.805 | 0.880 | 537.86 | 522.11 |

| 0.100 | 30 | 0.2356 | 0.0740 | 0.0692 | 0.0793 | 0.757 | 0.820 | 0.827 | 0.876 | 0.782 | 0.860 | 0.852 | 0.916 | 0.807 | 0.900 | 0.877 | 0.956 | 448.22 | 435.09 |

| 0.100 | 35 | 0.2749 | 0.0634 | 0.0593 | 0.0680 | 0.818 | 0.886 | 0.894 | 0.947 | 0.843 | 0.926 | 0.919 | 0.987 | 0.868 | 0.966 | 0.944 | 1.027 | 384.18 | 372.93 |

| 0.100 | 40 | 0.3142 | 0.0555 | 0.0519 | 0.0595 | 0.874 | 0.947 | 0.955 | 1.012 | 0.899 | 0.987 | 0.980 | 1.052 | 0.924 | 1.027 | 1.005 | 1.092 | 336.16 | 326.32 |

| 0.100 | 45 | 0.3534 | 0.0493 | 0.0461 | 0.0529 | 0.927 | 1.005 | 1.013 | 1.073 | 0.952 | 1.045 | 1.038 | 1.113 | 0.977 | 1.085 | 1.063 | 1.153 | 298.81 | 290.06 |

| 0.100 | 60 | 0.4712 | 0.0377 | 0.0353 | 0.0404 | 1.071 | 1.160 | 1.170 | 1.239 | 1.096 | 1.200 | 1.195 | 1.279 | 1.121 | 1.240 | 1.220 | 1.319 | 224.11 | 217.54 |

| 0.100 | 75 | 0.5890 | 0.0302 | 0.0282 | 0.0324 | 1.197 | 1.297 | 1.308 | 1.386 | 1.222 | 1.337 | 1.333 | 1.426 | 1.247 | 1.377 | 1.358 | 1.466 | 179.29 | 174.04 |

| 0.100 | 90 | 0.7069 | 0.0252 | 0.0235 | 0.0270 | 1.311 | 1.421 | 1.433 | 1.518 | 1.336 | 1.461 | 1.458 | 1.558 | 1.361 | 1.501 | 1.483 | 1.598 | 149.41 | 145.03 |

| 0.100 | 105 | 0.8247 | 0.0216 | 0.0201 | 0.0231 | 1.417 | 1.535 | 1.548 | 1.640 | 1.442 | 1.575 | 1.573 | 1.680 | 1.467 | 1.615 | 1.598 | 1.720 | 128.06 | 124.31 |

| 0.100 | 120 | 0.9425 | 0.0189 | 0.0176 | 0.0202 | 1.514 | 1.641 | 1.655 | 1.753 | 1.539 | 1.681 | 1.680 | 1.793 | 1.564 | 1.721 | 1.705 | 1.833 | 112.05 | 108.77 |

| 0.100 | 160 | 1.2566 | 0.0141 | 0.0132 | 0.0152 | 1.749 | 1.894 | 1.911 | 2.024 | 1.774 | 1.934 | 1.936 | 2.064 | 1.799 | 1.974 | 1.961 | 2.104 | 84.04 | 81.58 |

| 0.100 | 180 | 1.4137 | 0.0126 | 0.0118 | 0.0135 | 1.855 | 2.009 | 2.026 | 2.147 | 1.880 | 2.049 | 2.051 | 2.187 | 1.905 | 2.089 | 2.076 | 2.227 | 74.70 | 72.51 |

| 0.100 | 200 | 1.5708 | 0.0113 | 0.0106 | 0.0121 | 1.955 | 2.118 | 2.136 | 2.263 | 1.980 | 2.158 | 2.161 | 2.303 | 2.005 | 2.198 | 2.186 | 2.343 | 67.23 | 65.26 |

| 0.100 | 225 | 1.7671 | 0.0103 | 0.0096 | 0.0110 | 2.074 | 2.246 | 2.266 | 2.400 | 2.099 | 2.286 | 2.291 | 2.440 | 2.124 | 2.326 | 2.316 | 2.480 | 59.76 | 58.01 |

| 0.100 | 270 | 2.1206 | 0.0085 | 0.0080 | 0.0092 | 2.272 | 2.461 | 2.482 | 2.629 | 2.297 | 2.501 | 2.507 | 2.669 | 2.322 | 2.541 | 2.532 | 2.709 | 49.80 | 48.34 |

| 0.100 | 600 | 4.7124 | 0.0038 | 0.0036 | 0.0041 | 3.386 | 3.668 | 3.700 | 3.919 | 3.411 | 3.708 | 3.725 | 3.959 | 3.436 | 3.748 | 3.750 | 3.999 | 22.41 | 21.75 |

| 0.100 | 800 | 6.2832 | 0.0029 | 0.0027 | 0.0031 | 3.910 | 4.236 | 4.272 | 4.525 | 3.935 | 4.276 | 4.297 | 4.565 | 3.960 | 4.316 | 4.322 | 4.605 | 16.81 | 16.32 |

| 0.120 | 4 | 0.0452 | 0.3853 | 0.3636 | 0.4090 | 0.325 | 0.345 | 0.348 | 0.370 | 0.350 | 0.385 | 0.373 | 0.410 | 0.375 | 0.425 | 0.398 | 0.450 | 2340.72 | 2280.74 |

| 0.120 | 8 | 0.0905 | 0.1927 | 0.1818 | 0.2045 | 0.460 | 0.488 | 0.491 | 0.523 | 0.485 | 0.528 | 0.516 | 0.563 | 0.510 | 0.568 | 0.541 | 0.603 | 1170.36 | 1140.37 |

| 0.120 | 10 | 0.1131 | 0.1541 | 0.1455 | 0.1636 | 0.514 | 0.545 | 0.549 | 0.585 | 0.539 | 0.585 | 0.574 | 0.625 | 0.564 | 0.625 | 0.599 | 0.665 | 936.29 | 912.30 |

| 0.120 | 15 | 0.1696 | 0.1027 | 0.0970 | 0.1091 | 0.634 | 0.673 | 0.678 | 0.722 | 0.659 | 0.713 | 0.703 | 0.762 | 0.684 | 0.753 | 0.728 | 0.802 | 624.19 | 608.20 |

| 0.120 | 20 | 0.2262 | 0.0771 | 0.0727 | 0.0818 | 0.738 | 0.784 | 0.789 | 0.841 | 0.763 | 0.824 | 0.814 | 0.881 | 0.788 | 0.864 | 0.839 | 0.921 | 468.14 | 456.15 |

| 0.120 | 25 | 0.2827 | 0.0616 | 0.0582 | 0.0654 | 0.832 | 0.883 | 0.890 | 0.947 | 0.857 | 0.923 | 0.915 | 0.987 | 0.882 | 0.963 | 0.940 | 1.027 | 374.52 | 364.92 |

| 0.120 | 30 | 0.3393 | 0.0514 | 0.0485 | 0.0545 | 0.911 | 0.967 | 0.975 | 1.038 | 0.936 | 1.007 | 1.000 | 1.078 | 0.961 | 1.047 | 1.025 | 1.118 | 312.10 | 304.10 |

| 0.120 | 35 | 0.3958 | 0.0440 | 0.0416 | 0.0467 | 0.984 | 1.045 | 1.053 | 1.121 | 1.009 | 1.085 | 1.078 | 1.161 | 1.034 | 1.125 | 1.103 | 1.201 | 267.51 | 260.66 |

| 0.120 | 45 | 0.5089 | 0.0342 | 0.0323 | 0.0364 | 1.116 | 1.185 | 1.194 | 1.271 | 1.141 | 1.225 | 1.219 | 1.311 | 1.166 | 1.265 | 1.244 | 1.351 | 208.06 | 202.73 |

| 0.120 | 60 | 0.6786 | 0.0262 | 0.0247 | 0.0278 | 1.289 | 1.368 | 1.378 | 1.467 | 1.314 | 1.408 | 1.403 | 1.507 | 1.339 | 1.448 | 1.428 | 1.547 | 156.05 | 152.05 |

| 0.120 | 75 | 0.8482 | 0.0210 | 0.0198 | 0.0222 | 1.441 | 1.530 | 1.541 | 1.641 | 1.466 | 1.570 | 1.566 | 1.681 | 1.491 | 1.610 | 1.591 | 1.721 | 124.84 | 121.64 |

| 0.120 | 90 | 1.0179 | 0.0175 | 0.0165 | 0.0185 | 1.579 | 1.676 | 1.688 | 1.797 | 1.604 | 1.716 | 1.713 | 1.837 | 1.629 | 1.756 | 1.738 | 1.877 | 104.03 | 101.37 |

| 0.120 | 105 | 1.1875 | 0.0150 | 0.0141 | 0.0159 | 1.705 | 1.810 | 1.823 | 1.941 | 1.730 | 1.850 | 1.848 | 1.981 | 1.755 | 1.890 | 1.873 | 2.021 | 89.17 | 86.89 |

| 0.120 | 180 | 2.0358 | 0.0087 | 0.0082 | 0.0093 | 2.232 | 2.370 | 2.387 | 2.542 | 2.257 | 2.410 | 2.412 | 2.582 | 2.282 | 2.450 | 2.437 | 2.622 | 52.02 | 50.68 |

| 0.120 | 225 | 2.5447 | 0.0071 | 0.0067 | 0.0076 | 2.496 | 2.650 | 2.669 | 2.842 | 2.521 | 2.690 | 2.694 | 2.882 | 2.546 | 2.730 | 2.719 | 2.922 | 41.61 | 40.55 |

| 0.120 | 270 | 3.0536 | 0.0059 | 0.0056 | 0.0063 | 2.734 | 2.902 | 2.924 | 3.113 | 2.759 | 2.942 | 2.949 | 3.153 | 2.784 | 2.982 | 2.974 | 3.193 | 34.68 | 33.79 |

| 0.120 | 600 | 6.7858 | 0.0027 | 0.0025 | 0.0028 | 4.076 | 4.327 | 4.358 | 4.640 | 4.101 | 4.367 | 4.383 | 4.680 | 4.126 | 4.407 | 4.408 | 4.720 | 15.60 | 15.20 |

| 0.140 | 4 | 0.0616 | 0.2832 | 0.2691 | 0.2982 | 0.378 | 0.400 | 0.403 | 0.428 | 0.403 | 0.440 | 0.428 | 0.468 | 0.428 | 0.480 | 0.453 | 0.508 | 1723.00 | 1681.32 |

| 0.140 | 10 | 0.1539 | 0.1133 | 0.1076 | 0.1193 | 0.597 | 0.632 | 0.636 | 0.676 | 0.622 | 0.672 | 0.661 | 0.716 | 0.647 | 0.712 | 0.686 | 0.756 | 689.20 | 672.53 |

| 0.140 | 20 | 0.3079 | 0.0566 | 0.0538 | 0.0596 | 0.858 | 0.909 | 0.914 | 0.971 | 0.883 | 0.949 | 0.939 | 1.011 | 0.908 | 0.989 | 0.964 | 1.051 | 344.60 | 336.26 |

| 0.140 | 30 | 0.4618 | 0.0378 | 0.0359 | 0.0398 | 1.059 | 1.122 | 1.129 | 1.199 | 1.084 | 1.162 | 1.154 | 1.239 | 1.109 | 1.202 | 1.179 | 1.279 | 229.73 | 224.18 |

| 0.140 | 45 | 0.6927 | 0.0252 | 0.0239 | 0.0265 | 1.297 | 1.374 | 1.382 | 1.468 | 1.322 | 1.414 | 1.407 | 1.508 | 1.347 | 1.454 | 1.432 | 1.548 | 153.16 | 149.45 |

| 0.140 | 60 | 0.9236 | 0.0192 | 0.0183 | 0.0203 | 1.497 | 1.586 | 1.596 | 1.695 | 1.522 | 1.626 | 1.621 | 1.735 | 1.547 | 1.666 | 1.646 | 1.775 | 114.87 | 112.09 |

| 0.140 | 75 | 1.1545 | 0.0154 | 0.0146 | 0.0162 | 1.674 | 1.774 | 1.785 | 1.896 | 1.699 | 1.814 | 1.810 | 1.936 | 1.724 | 1.854 | 1.835 | 1.976 | 91.89 | 89.67 |

| 0.140 | 90 | 1.3854 | 0.0128 | 0.0122 | 0.0135 | 1.834 | 1.943 | 1.955 | 2.076 | 1.859 | 1.983 | 1.980 | 2.116 | 1.884 | 2.023 | 2.005 | 2.156 | 76.58 | 74.73 |

| 0.140 | 100 | 1.5394 | 0.0115 | 0.0110 | 0.0122 | 1.933 | 2.048 | 2.061 | 2.189 | 1.958 | 2.088 | 2.086 | 2.229 | 1.983 | 2.128 | 2.111 | 2.269 | 68.92 | 67.25 |

| 0.140 | 120 | 1.8473 | 0.0096 | 0.0091 | 0.0101 | 2.117 | 2.243 | 2.257 | 2.398 | 2.142 | 2.283 | 2.282 | 2.438 | 2.167 | 2.323 | 2.307 | 2.478 | 57.43 | 56.04 |

| 0.140 | 150 | 2.3091 | 0.0077 | 0.0073 | 0.0081 | 2.367 | 2.508 | 2.524 | 2.681 | 2.392 | 2.548 | 2.549 | 2.721 | 2.417 | 2.588 | 2.574 | 2.761 | 45.95 | 44.84 |

| 0.140 | 200 | 3.0788 | 0.0058 | 0.0055 | 0.0061 | 2.733 | 2.896 | 2.914 | 3.095 | 2.758 | 2.936 | 2.939 | 3.135 | 2.783 | 2.976 | 2.964 | 3.175 | 34.46 | 33.63 |

| 0.140 | 225 | 3.4636 | 0.0052 | 0.0050 | 0.0055 | 2.899 | 3.072 | 3.091 | 3.283 | 2.924 | 3.112 | 3.116 | 3.323 | 2.949 | 3.152 | 3.141 | 3.363 | 30.63 | 29.89 |

| 0.140 | 270 | 4.1563 | 0.0044 | 0.0041 | 0.0046 | 3.176 | 3.365 | 3.386 | 3.597 | 3.201 | 3.405 | 3.411 | 3.637 | 3.226 | 3.445 | 3.436 | 3.677 | 25.53 | 24.91 |

| 0.150 | 4 | 0.0707 | 0.2467 | 0.2351 | 0.2591 | 0.405 | 0.428 | 0.430 | 0.455 | 0.430 | 0.468 | 0.455 | 0.495 | 0.455 | 0.508 | 0.480 | 0.535 | 1501.26 | 1467.40 |

| 0.150 | 10 | 0.1767 | 0.0987 | 0.0940 | 0.1036 | 0.640 | 0.676 | 0.680 | 0.719 | 0.665 | 0.716 | 0.705 | 0.759 | 0.690 | 0.756 | 0.730 | 0.799 | 600.51 | 586.96 |

| 0.150 | 20 | 0.3534 | 0.0493 | 0.0470 | 0.0518 | 0.920 | 0.971 | 0.977 | 1.034 | 0.945 | 1.011 | 1.002 | 1.074 | 0.970 | 1.051 | 1.027 | 1.114 | 300.25 | 293.48 |

| 0.150 | 30 | 0.5301 | 0.0329 | 0.0313 | 0.0345 | 1.136 | 1.199 | 1.206 | 1.276 | 1.161 | 1.239 | 1.231 | 1.316 | 1.186 | 1.279 | 1.256 | 1.356 | 200.17 | 195.65 |

| 0.150 | 45 | 0.7952 | 0.0219 | 0.0209 | 0.0230 | 1.391 | 1.468 | 1.477 | 1.563 | 1.416 | 1.508 | 1.502 | 1.603 | 1.441 | 1.548 | 1.527 | 1.643 | 133.45 | 130.44 |

| 0.150 | 60 | 1.0603 | 0.0168 | 0.0160 | 0.0176 | 1.606 | 1.695 | 1.705 | 1.805 | 1.631 | 1.735 | 1.730 | 1.845 | 1.656 | 1.775 | 1.755 | 1.885 | 100.08 | 97.83 |

| 0.150 | 75 | 1.3254 | 0.0134 | 0.0128 | 0.0141 | 1.796 | 1.896 | 1.907 | 2.017 | 1.821 | 1.936 | 1.932 | 2.057 | 1.846 | 1.976 | 1.957 | 2.097 | 80.07 | 78.26 |

| 0.150 | 90 | 1.5904 | 0.0112 | 0.0107 | 0.0117 | 1.967 | 2.076 | 2.089 | 2.210 | 1.992 | 2.116 | 2.114 | 2.250 | 2.017 | 2.156 | 2.139 | 2.290 | 66.72 | 65.22 |

| 0.150 | 100 | 1.7671 | 0.0101 | 0.0096 | 0.0106 | 2.074 | 2.189 | 2.202 | 2.330 | 2.099 | 2.229 | 2.227 | 2.370 | 2.124 | 2.269 | 2.252 | 2.410 | 60.05 | 58.70 |

| 0.150 | 120 | 2.1206 | 0.0084 | 0.0080 | 0.0088 | 2.272 | 2.398 | 2.412 | 2.552 | 2.297 | 2.438 | 2.437 | 2.592 | 2.322 | 2.478 | 2.462 | 2.632 | 50.04 | 48.91 |

| 0.150 | 150 | 2.6507 | 0.0067 | 0.0064 | 0.0070 | 2.540 | 2.681 | 2.696 | 2.853 | 2.565 | 2.721 | 2.721 | 2.893 | 2.590 | 2.761 | 2.746 | 2.933 | 40.03 | 39.13 |

| 0.150 | 200 | 3.5343 | 0.0050 | 0.0048 | 0.0053 | 2.933 | 3.095 | 3.114 | 3.295 | 2.958 | 3.135 | 3.139 | 3.335 | 2.983 | 3.175 | 3.164 | 3.375 | 30.03 | 29.35 |

| 0.150 | 225 | 3.9761 | 0.0046 | 0.0043 | 0.0048 | 3.110 | 3.283 | 3.302 | 3.494 | 3.135 | 3.323 | 3.327 | 3.534 | 3.160 | 3.363 | 3.352 | 3.574 | 26.69 | 26.09 |

| 0.150 | 270 | 4.7713 | 0.0038 | 0.0036 | 0.0040 | 3.407 | 3.597 | 3.618 | 3.828 | 3.432 | 3.637 | 3.643 | 3.868 | 3.457 | 3.677 | 3.668 | 3.908 | 22.24 | 21.74 |

| 0.160 | 4 | 0.0804 | 0.2168 | 0.2071 | 0.2271 | 0.430 | 0.455 | 0.458 | 0.485 | 0.455 | 0.495 | 0.483 | 0.525 | 0.480 | 0.535 | 0.508 | 0.565 | 1321.05 | 1290.51 |

| 0.160 | 10 | 0.2011 | 0.0867 | 0.0828 | 0.0908 | 0.680 | 0.719 | 0.723 | 0.767 | 0.705 | 0.759 | 0.748 | 0.807 | 0.730 | 0.799 | 0.773 | 0.847 | 528.42 | 516.20 |

| 0.160 | 20 | 0.4021 | 0.0434 | 0.0414 | 0.0454 | 0.977 | 1.034 | 1.039 | 1.102 | 1.002 | 1.074 | 1.064 | 1.142 | 1.027 | 1.114 | 1.089 | 1.182 | 264.21 | 258.10 |

| 0.160 | 30 | 0.6032 | 0.0289 | 0.0276 | 0.0303 | 1.206 | 1.276 | 1.283 | 1.360 | 1.231 | 1.316 | 1.308 | 1.400 | 1.256 | 1.356 | 1.333 | 1.440 | 176.14 | 172.07 |

| 0.160 | 45 | 0.9048 | 0.0193 | 0.0184 | 0.0202 | 1.477 | 1.563 | 1.571 | 1.666 | 1.502 | 1.603 | 1.596 | 1.706 | 1.527 | 1.643 | 1.621 | 1.746 | 117.43 | 114.71 |

| 0.160 | 60 | 1.2064 | 0.0147 | 0.0141 | 0.0154 | 1.705 | 1.805 | 1.814 | 1.923 | 1.730 | 1.845 | 1.839 | 1.963 | 1.755 | 1.885 | 1.864 | 2.003 | 88.07 | 86.03 |

| 0.160 | 75 | 1.5080 | 0.0118 | 0.0113 | 0.0123 | 1.907 | 2.017 | 2.029 | 2.151 | 1.932 | 2.057 | 2.054 | 2.191 | 1.957 | 2.097 | 2.079 | 2.231 | 70.46 | 68.83 |

| 0.160 | 90 | 1.8096 | 0.0098 | 0.0094 | 0.0103 | 2.089 | 2.210 | 2.222 | 2.356 | 2.114 | 2.250 | 2.247 | 2.396 | 2.139 | 2.290 | 2.272 | 2.436 | 58.71 | 57.36 |

| 0.160 | 100 | 2.0106 | 0.0088 | 0.0084 | 0.0093 | 2.202 | 2.330 | 2.342 | 2.483 | 2.227 | 2.370 | 2.367 | 2.523 | 2.252 | 2.410 | 2.392 | 2.563 | 52.84 | 51.62 |

| 0.160 | 120 | 2.4127 | 0.0074 | 0.0070 | 0.0077 | 2.412 | 2.552 | 2.2566 | 2.720 | 2.437 | 2.592 | 2.591 | 2.760 | 2.462 | 2.632 | 2.616 | 2.800 | 44.04 | 43.02 |

| 0.160 | 150 | 3.0159 | 0.0059 | 0.0056 | 0.0062 | 2.696 | 2.853 | 2.869 | 3.041 | 2.721 | 2.893 | 2.894 | 3.081 | 2.746 | 2.933 | 2.919 | 3.121 | 35.23 | 34.41 |

| 0.160 | 200 | 4.0212 | 0.0044 | 0.0042 | 0.0046 | 3.114 | 3.295 | 3.313 | 3.512 | 3.139 | 3.335 | 3.338 | 3.552 | 3.164 | 3.375 | 3.363 | 3.592 | 26.42 | 25.81 |

| 0.160 | 225 | 4.5239 | 0.0040 | 0.0038 | 0.0042 | 3.302 | 3.494 | 3.514 | 3.725 | 3.327 | 3.534 | 3.539 | 3.765 | 3.352 | 3.574 | 3.564 | 3.805 | 23.49 | 22.94 |

| 0.160 | 270 | 5.4287 | 0.0033 | 0.0032 | 0.0035 | 3.618 | 3.828 | 3.849 | 4.080 | 3.643 | 3.868 | 3.874 | 4.120 | 3.668 | 3.908 | 3.899 | 4.160 | 19.57 | 19.12 |

| 0.180 | 4 | 0.1018 | 0.1713 | 0.1643 | 0.1787 | 0.483 | 0.510 | 0.513 | 0.543 | 0.508 | 0.550 | 0.538 | 0.583 | 0.533 | 0.590 | 0.563 | 0.623 | 1044.95 | 1021.66 |

| 0.180 | 5 | 0.1272 | 0.1370 | 0.1315 | 0.1429 | 0.539 | 0.570 | 0.573 | 0.607 | 0.564 | 0.610 | 0.598 | 0.647 | 0.589 | 0.650 | 0.623 | 0.687 | 835.96 | 817.33 |

| 0.180 | 10 | 0.2545 | 0.0685 | 0.0657 | 0.0715 | 0.763 | 0.806 | 0.810 | 0.858 | 0.788 | 0.846 | 0.835 | 0.898 | 0.813 | 0.886 | 0.860 | 0.938 | 417.98 | 408.33 |

| 0.180 | 20 | 0.5089 | 0.0343 | 0.0329 | 0.0357 | 1.096 | 1.159 | 1.164 | 1.232 | 1.121 | 1.199 | 1.189 | 1.272 | 1.146 | 1.239 | 1.214 | 1.312 | 208.99 | 204.33 |

| 0.180 | 30 | 0.7634 | 0.0228 | 0.0219 | 0.0238 | 1.353 | 1.430 | 1.437 | 1.521 | 1.378 | 1.470 | 1.462 | 1.561 | 1.403 | 1.510 | 1.487 | 1.601 | 139.33 | 136.22 |

| 0.180 | 45 | 1.1451 | 0.0152 | 0.0146 | 0.0159 | 1.657 | 1.752 | 1.760 | 1.863 | 1.682 | 1.792 | 1.785 | 1.903 | 1.707 | 1.832 | 1.810 | 1.943 | 92.88 | 90.81 |

| 0.180 | 60 | 1.5268 | 0.0116 | 0.0112 | 0.0121 | 1.914 | 2.023 | 2.033 | 2.152 | 1.939 | 2.063 | 2.058 | 2.192 | 1.964 | 2.103 | 2.083 | 2.232 | 69.66 | 68.11 |

| 0.180 | 75 | 1.9085 | 0.0093 | 0.0089 | 0.0097 | 2.139 | 2.261 | 2.272 | 2.405 | 2.164 | 2.301 | 2.297 | 2.445 | 2.189 | 2.341 | 2.322 | 2.485 | 55.73 | 54.49 |

| 0.180 | 90 | 2.2902 | 0.0078 | 0.0074 | 0.0081 | 0.344 | 2.477 | 2.489 | 2.635 | 2.369 | 2.517 | 2.514 | 2.675 | 2.394 | 2.557 | 2.539 | 2.715 | 46.44 | 45.41 |

| 0.180 | 100 | 2.5447 | 0.0070 | 0.0067 | 0.0073 | 2.470 | 2.611 | 2.624 | 2.778 | 2.495 | 2.651 | 2.649 | 2.818 | 2.520 | 2.691 | 2.674 | 2.858 | 41.80 | 40.87 |

| 0.180 | 120 | 3.0536 | 0.0058 | 0.0056 | 0.0061 | 2.706 | 2.860 | 2.874 | 3.043 | 2.731 | 2.2900 | 2.899 | 3.083 | 2.756 | 2.940 | 2.2924 | 3.123 | 34.83 | 34.06 |

| 0.180 | 150 | 3.8170 | 0.0047 | 0.0045 | 0.0049 | 3.026 | 3.198 | 3.214 | 3.402 | 3.051 | 3.238 | 3.239 | 3.442 | 3.076 | 3.278 | 3.264 | 3.482 | 27.87 | 27.24 |

| 0.180 | 200 | 5.0894 | 0.0035 | 0.0034 | 0.0036 | 3.494 | 3.693 | 3.711 | 3.928 | 3.519 | 3.733 | 3.736 | 3.968 | 3.544 | 3.773 | 3.761 | 4.008 | 20.90 | 20.43 |

| 0.180 | 270 | 6.8707 | 0.0026 | 0.0025 | 0.0028 | 4.059 | 4.291 | 4.312 | 4.564 | 4.084 | 4.331 | 4.337 | 4.604 | 4.109 | 4.371 | 4.362 | 4.644 | 15.48 | 15.14 |

| 0.200 | 4 | 0.1257 | 0.1387 | 0.1335 | 0.1443 | 0.535 | 0.565 | 0.568 | 0.598 | 0.560 | 0.605 | 0.593 | 0.638 | 0.585 | 0.645 | 0.618 | 0.678 | 847.16 | 829.52 |

| 0.200 | 10 | 0.3142 | 0.0555 | 0.0534 | 0.0577 | 0.846 | 0.893 | 0.897 | 0.945 | 0.871 | 0.933 | 0.922 | 0.985 | 0.896 | 0.973 | 0.947 | 1.025 | 338.86 | 331.81 |

| 0.200 | 15 | 0.4712 | 0.0370 | 0.0356 | 0.0385 | 1.044 | 1.103 | 1.108 | 1.166 | 1.069 | 1.143 | 1.133 | 1.206 | 1.094 | 1.183 | 1.158 | 1.246 | 225.91 | 221.20 |

| 0.200 | 20 | 0.6283 | 0.0277 | 0.0267 | 0.0289 | 1.215 | 1.284 | 1.289 | 1.357 | 1.240 | 1.324 | 1.314 | 1.397 | 1.265 | 1.364 | 1.339 | 1.437 | 169.43 | 165.90 |

| 0.200 | 25 | 0.7854 | 0.222 | 0.0214 | 0.0231 | 1.370 | 1.446 | 1.453 | 1.530 | 1.395 | 1.486 | 1.478 | 1.570 | 1.420 | 1.526 | 1.503 | 1.610 | 135.54 | 132.72 |

| 0.200 | 30 | 0.9425 | 0.0185 | 0.0178 | 0.0192 | 1.500 | 1.584 | 1.591 | 1.676 | 1.525 | 1.624 | 1.616 | 1.716 | 1.550 | 1.664 | 1.641 | 1.756 | 112.95 | 110.60 |

| 0.200 | 45 | 1.4137 | 0.0123 | 0.0119 | 0.0128 | 1.838 | 1.941 | 1.949 | 2.052 | 1.863 | 1.981 | 1.974 | 2.092 | 1.888 | 2.021 | 1.999 | 2.132 | 75.30 | 73.73 |

| 0.200 | 60 | 1.8850 | 0.0094 | 0.0091 | 0.0098 | 2.122 | 2.241 | 2.251 | 2.370 | 2.147 | 2.281 | 2.276 | 2.410 | 2.172 | 2.321 | 2.301 | 2.450 | 56.48 | 55.30 |

| 0.200 | 75 | 2.3562 | 0.0075 | 0.0073 | 0.0078 | 2.372 | 2.505 | 2.516 | 2.649 | 2.397 | 2.545 | 2.541 | 2.689 | 2.422 | 2.585 | 2.566 | 2.729 | 45.18 | 44.24 |

| 0.200 | 90 | 2.8274 | 0.0063 | 0.0061 | 0.0065 | 2.599 | 2.744 | 2.756 | 2.902 | 2.624 | 2.784 | 2.781 | 2.942 | 2.649 | 2.824 | 2.806 | 2.982 | 37.65 | 36.87 |

| 0.200 | 100 | 3.1416 | 0.0057 | 0.0054 | 0.0059 | 2.739 | 2.893 | 2.906 | 3.059 | 2.764 | 2.933 | 2.931 | 3.099 | 2.789 | 2.973 | 2.956 | 3.139 | 33.89 | 33.18 |

| 0.200 | 120 | 3.7699 | 0.0047 | 0.0045 | 0.0049 | 3.001 | 3.169 | 3.183 | 3.351 | 3.026 | 3.209 | 3.208 | 3.391 | 3.051 | 3.249 | 3.233 | 3.431 | 28.24 | 27.65 |

| 0.200 | 150 | 4.7124 | 0.0038 | 0.0036 | 0.0039 | 3.355 | 3.543 | 3.559 | 3.747 | 3.380 | 3.583 | 3.584 | 3.787 | 3.405 | 3.623 | 3.609 | 3.827 | 22.59 | 22.12 |

| 0.200 | 200 | 6.2832 | 0.0028 | 0.0027 | 0.0029 | 3.874 | 4.091 | 4.109 | 4.326 | 3.899 | 4.131 | 4.134 | 4.366 | 3.924 | 4.171 | 4.159 | 4.406 | 16.94 | 16.59 |

| 0.250 | 2 | 0.0982 | 0.1776 | 0.1706 | 0.1850 | 0.472 | 0.497 | 0.499 | 0.525 | 0.497 | 0.537 | 0.524 | 0.565 | 0.522 | 0.577 | 0.549 | 0.605 | 1085.74 | 1064.23 |

| 0.250 | 4 | 0.1963 | 0.0888 | 0.0853 | 0.0925 | 0.668 | 0.703 | 0.705 | 0.743 | 0.693 | 0.743 | 0.730 | 0.783 | 0.718 | 0.783 | 0.755 | 0.823 | 542.87 | 532.12 |

| 0.250 | 10 | 0.4909 | 0.0355 | 0.0341 | 0.0370 | 1.055 | 1.111 | 1.115 | 1.174 | 1.080 | 1.151 | 1.140 | 1.214 | 1.105 | 1.191 | 1.165 | 1.254 | 217.15 | 212.85 |

| 0.250 | 15 | 0.7363 | 0.0237 | 0.0227 | 0.0247 | 1.303 | 1.371 | 1.376 | 1.449 | 1.328 | 1.411 | 1.401 | 1.489 | 1.353 | 1.451 | 1.426 | 1.529 | 144.76 | 141.90 |

| 0.250 | 20 | 0.9817 | 0.0178 | 0.0171 | 0.0185 | 1.516 | 1.596 | 1.602 | 1.687 | 1.541 | 1.636 | 1.627 | 1.727 | 1.566 | 1.676 | 1.652 | 1.767 | 108.57 | 106.42 |

| 0.250 | 30 | 1.4726 | 0.0118 | 0.0114 | 0.0123 | 1.872 | 1.970 | 1.977 | 2.082 | 1.897 | 2.010 | 2.002 | 2.122 | 1.922 | 2.050 | 2.027 | 2.162 | 72.38 | 70.95 |

| 0.250 | 45 | 2.2089 | 0.0079 | 0.0076 | 0.0082 | 2.293 | 2.413 | 2.421 | 2.550 | 2.318 | 2.453 | 2.446 | 2.590 | 2.343 | 2.493 | 2.471 | 2.630 | 48.25 | 47.30 |

| 0.250 | 60 | 2.9452 | 0.0060 | 0.0058 | 0.0063 | 2.647 | 2.786 | 2.796 | 2.945 | 2.672 | 2.826 | 2.821 | 2.985 | 2.697 | 2.866 | 2.846 | 3.025 | 36.19 | 35.47 |

| 0.250 | 75 | 3.6816 | 0.0048 | 0.0046 | 0.0050 | 2.960 | 3.115 | 3.126 | 3.292 | 2.985 | 3.155 | 3.151 | 3.332 | 3.010 | 3.195 | 3.176 | 3.372 | 28.95 | 28.38 |

| 0.250 | 90 | 4.4179 | 0.0040 | 0.0039 | 0.0042 | 3.242 | 3.412 | 3.424 | 3.607 | 3.267 | 3.452 | 3.449 | 3.647 | 3.292 | 3.492 | 3.474 | 3.687 | 24.13 | 23.65 |

| 0.300 | 2 | 0.1414 | 0.1233 | 0.1191 | 0.1278 | 0.564 | 0.590 | 0.592 | 0.622 | 0.589 | 0.630 | 0.617 | 0.662 | 0.614 | 0.670 | 0.642 | 0.702 | 755.81 | 742.20 |

| 0.300 | 10 | 0.7069 | 0.0247 | 0.0238 | 0.0256 | 1.261 | 1.320 | 1.324 | 1.391 | 1.286 | 1.360 | 1.349 | 1.431 | 1.311 | 1.400 | 1.374 | 1.471 | 151.16 | 148.44 |

| 0.300 | 15 | 1.0603 | 0.0164 | 0.0159 | 0.0170 | 1.1557 | 1.630 | 1.635 | 1.718 | 1.582 | 1.670 | 1.660 | 1.758 | 1.607 | 1.710 | 1.685 | 1.798 | 100.78 | 98.96 |

| 0.300 | 20 | 1.4137 | 0.0123 | 0.0119 | 0.0128 | 1.812 | 1.897 | 1.903 | 1.999 | 1.837 | 1.937 | 1.928 | 2.039 | 1.862 | 1.977 | 1.953 | 2.079 | 75.58 | 74.22 |

| 0.300 | 30 | 2.1206 | 0.0082 | 0.0079 | 0.0085 | 2.236 | 2.342 | 2.349 | 2.468 | 2.261 | 2.382 | 2.374 | 2.508 | 2.286 | 2.422 | 2.399 | 2.548 | 50.39 | 49.48 |

| 0.300 | 45 | 3.1809 | 0.0055 | 0.0053 | 0.0057 | 2.739 | 2.868 | 2.876 | 3.022 | 2.764 | 2.908 | 2.901 | 3.062 | 2.789 | 2.948 | 2.926 | 3.102 | 33.59 | 32.99 |

| 0.300 | 60 | 4.2412 | 0.0042 | 0.0040 | 0.0043 | 3.163 | 3.312 | 3.321 | 3.490 | 3.188 | 3.352 | 3.346 | 3.530 | 3.213 | 3.392 | 3.371 | 3.570 | 25.19 | 24.74 |

| 0.300 | 75 | 5.3014 | 0.0034 | 0.0032 | 0.0035 | 3.536 | 3.702 | 3.714 | 3.902 | 3.561 | 3.742 | 3.739 | 3.942 | 3.586 | 3.782 | 3.764 | 3.982 | 20.16 | 19.79 |

| 0.300 | 90 | 6.3617 | 0.0028 | 0.0027 | 0.0029 | 3.874 | 4.056 | 4.068 | 4.274 | 3.899 | 4.096 | 4.093 | 4.314 | 3.924 | 4.136 | 4.118 | 4.354 | 16.80 | 16.49 |

| 0.355 | 4 | 0.3959 | 0.0440 | 0.0427 | 0.0454 | 0.938 | 0.980 | 0.983 | 1.028 | 0.963 | 1.020 | 1.008 | 1.068 | 0.988 | 1.060 | 1.033 | 1.108 | 270.56 | 266.11 |

| 0.355 | 6 | 0.5939 | 0.0294 | 0.0285 | 0.0303 | 1.148 | 1.200 | 1.203 | 1.258 | 1.173 | 1.240 | 1.228 | 1.298 | 1.198 | 1.280 | 1.253 | 1.338 | 180.38 | 177.40 |

| 0.355 | 10 | 0.9898 | 0.0176 | 0.0171 | 0.0182 | 1.482 | 1.550 | 1.553 | 1.625 | 1.507 | 1.590 | 1.578 | 1.665 | 1.532 | 1.630 | 1.603 | 1.705 | 108.23 | 106.44 |

| 0.355 | 15 | 1.4847 | 0.0117 | 0.0114 | 0.0121 | 1.830 | 1.913 | 1.918 | 2.006 | 1.855 | 1.953 | 1.943 | 2.046 | 1.880 | 1.993 | 1.968 | 2.086 | 72.15 | 70.96 |

| 0.355 | 20 | 1.9796 | 0.0088 | 0.0085 | 0.0091 | 2.130 | 2.226 | 2.232 | 2.334 | 2.155 | 2.266 | 2.257 | 2.374 | 2.180 | 2.306 | 2.282 | 2.414 | 54.11 | 53.22 |

| 0.355 | 30 | 2.9694 | 0.0059 | 0.0057 | 0.0061 | 2.629 | 2.748 | 2.755 | 2.881 | 2.654 | 2.788 | 2.780 | 2.921 | 2.679 | 2.828 | 2.805 | 2.961 | 36.08 | 35.48 |

| 0.355 | 45 | 4.4541 | 0.0039 | 0.0038 | 0.0040 | 3.220 | 3.366 | 3.374 | 3.529 | 3.245 | 3.406 | 3.399 | 3.569 | 3.270 | 3.446 | 3.424 | 3.609 | 24.05 | 23.65 |

| 0.355 | 60 | 5.9388 | 0.0030 | 0.0029 | 0.0031 | 3.718 | 3.887 | 3.897 | 4.075 | 3.743 | 3.927 | 3.922 | 4.115 | 3.768 | 3.967 | 3.947 | 4.155 | 18.04 | 17.74 |

| 0.400 | 4 | 0.5027 | 0.0347 | 0.0336 | 0.0359 | 1.053 | 1.098 | 1.100 | 1.148 | 1.078 | 1.138 | 1.125 | 1.188 | 1.103 | 1.178 | 1.150 | 1.228 | 213.47 | 210.19 |

| 0.400 | 6 | 0.7540 | 0.0231 | 0.0224 | 0.0239 | 1.289 | 1.344 | 1.347 | 1.405 | 1.314 | 1.384 | 1.372 | 1.445 | 1.339 | 1.424 | 1.397 | 1.485 | 142.31 | 140.12 |

| 0.400 | 10 | 1.2566 | 0.0139 | 0.0134 | 0.0144 | 1.664 | 1.735 | 1.739 | 1.814 | 1.689 | 1.775 | 1.764 | 1.854 | 1.714 | 1.815 | 1.789 | 1.894 | 85.39 | 84.07 |

| 0.400 | 15 | 1.8850 | 0.0092 | 0.0089 | 0.0096 | 2.054 | 2.142 | 2.147 | 2.240 | 2.079 | 2.182 | 2.172 | 2.280 | 2.104 | 2.222 | 2.197 | 2.230 | 56.92 | 56.05 |

| 0.400 | 20 | 2.5133 | 0.0069 | 0.0067 | 0.0072 | 2.391 | 2.493 | 2.499 | 2.607 | 2.416 | 2.533 | 2.524 | 2.647 | 2.441 | 2.573 | 2.549 | 2.687 | 42.69 | 42.04 |

| 0.400 | 30 | 3.7699 | 0.0046 | 0.0045 | 0.0048 | 2.952 | 3.078 | 3.085 | 3.218 | 2.977 | 3.118 | 3.110 | 3.258 | 3.002 | 3.158 | 3.135 | 3.298 | 28.46 | 28.02 |

| 0.400 | 35 | 4.3982 | 0.0040 | 0.0038 | 0.0041 | 3.188 | 3.324 | 3.332 | 3.476 | 3.213 | 3.364 | 3.357 | 3.516 | 3.238 | 3.404 | 3.382 | 3.556 | 24.40 | 24.02 |

| 0.500 | 4 | 0.7854 | 0.0222 | 0.0216 | 0.0228 | 1.310 | 1.360 | 1.363 | 1.415 | 1.335 | 1.400 | 1.388 | 1.455 | 1.360 | 1.440 | 1.413 | 1.495 | 136.92 | 135.07 |

| 0.500 | 6 | 1.1781 | 0.0148 | 0.0144 | 0.0152 | 1.604 | 1.666 | 1.669 | 1.733 | 1.629 | 1.706 | 1.694 | 1.773 | 1.654 | 1.746 | 1.719 | 1.813 | 91.28 | 90.05 |

| 0.500 | 10 | 1.9635 | 0.0089 | 0.0086 | 0.0091 | 2.071 | 2.150 | 2.154 | 2.237 | 2.096 | 2.190 | 2.179 | 2.277 | 2.121 | 2.230 | 2.204 | 2.317 | 54.77 | 54.03 |

| 0.500 | 15 | 2.9452 | 0.0059 | 0.0058 | 0.0061 | 2.557 | 2.655 | 2.660 | 2.762 | 2.582 | 2.695 | 2.685 | 2.802 | 2.607 | 2.735 | 2.710 | 2.842 | 36.51 | 36.00 |

| 0.500 | 20 | 3.9270 | 0.0044 | 0.0043 | 0.0046 | 2.976 | 3.090 | 3.095 | 3.215 | 3.001 | 3.130 | 3.120 | 3.255 | 3.026 | 3.170 | 3.145 | 3.295 | 27.38 | 27.01 |

| 0.500 | 30 | 5.8905 | 0.0030 | 0.0029 | 0.0030 | 3.674 | 3.814 | 3.821 | 3.968 | 3.699 | 3.854 | 3.846 | 4.008 | 3.724 | 3.894 | 3.871 | 4.048 | 18.26 | 18.01 |

| 0.500 | 35 | 6.8722 | 0.0025 | 0.0025 | 0.0026 | 3.968 | 4.119 | 4.127 | 4.286 | 3.993 | 4.159 | 4.152 | 4.326 | 4.018 | 4.199 | 4.177 | 4.366 | 15.65 | 15.44 |

Other dimensions and constructions on request. All data are based on EN 60317-11.

EW Types

Enamelled Wire Types

General

There is a big variety of enamelled wire types available. The different insulations are described in different standards, such as IEC 60317 (Asia or Europe), NEMA MW 1000 (USA) and JIS C 3202 (Japan) which sometimes still use different test methods.

For NEMA MW 1000C values are given in inch and metric.

Under the respective standard (customized to the region where appropriate), the typical technical values are given for the different insulation, such as Polyurethane, Polyester, Polyesterimide, Polyimide.

Europe

Enamelled Copper Wire acc. to IEC - Europe

IEC 60317 specifies different enamelled wire types. Test methods referred to are IEC 60851.

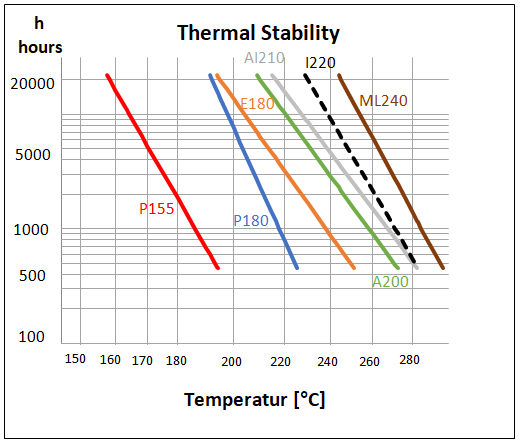

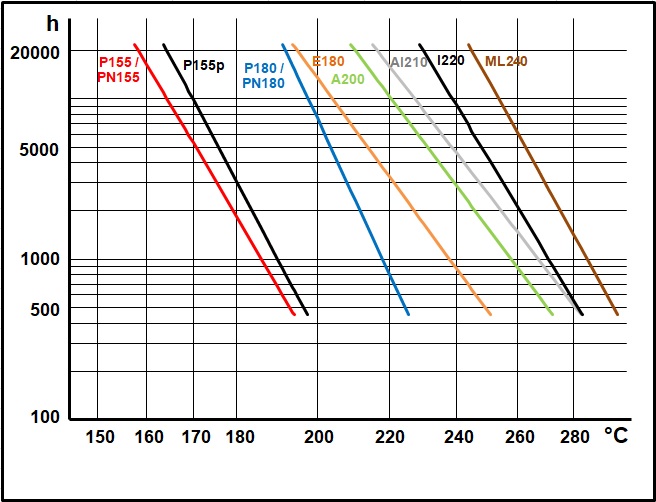

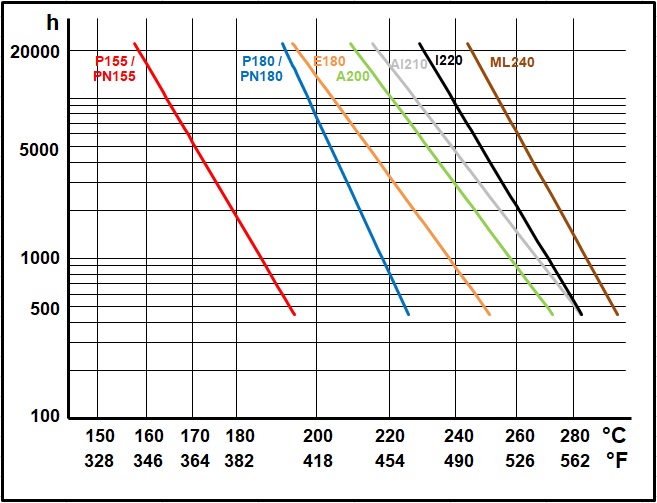

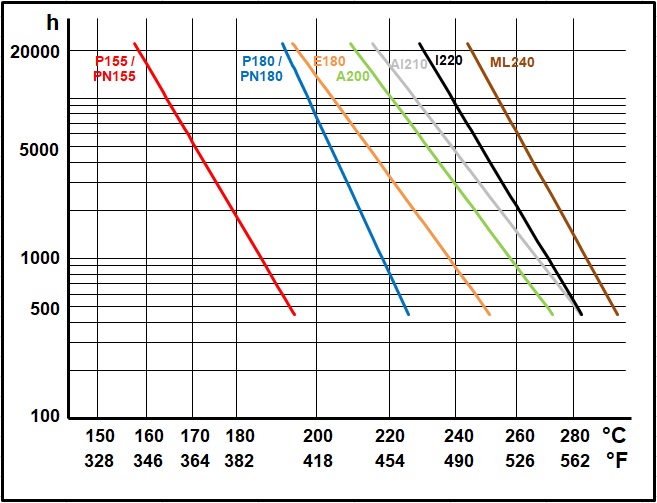

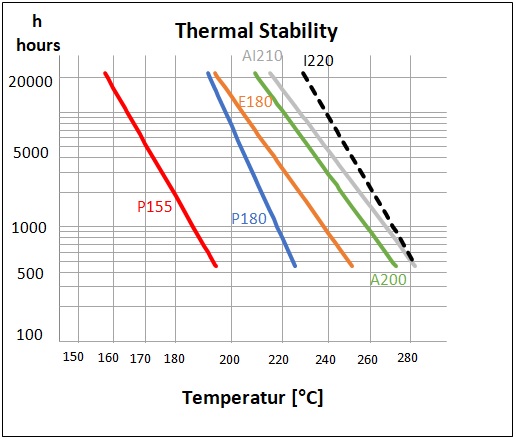

Thermal Stability acc. to IEC 60172

The line chart below is for technical comparison only and cannot be used to forecast lifetime of wound products (see also IEC 60172)

Thermal Stability in Hours [h] vs. Temperature in Degrees Celsius [°C]

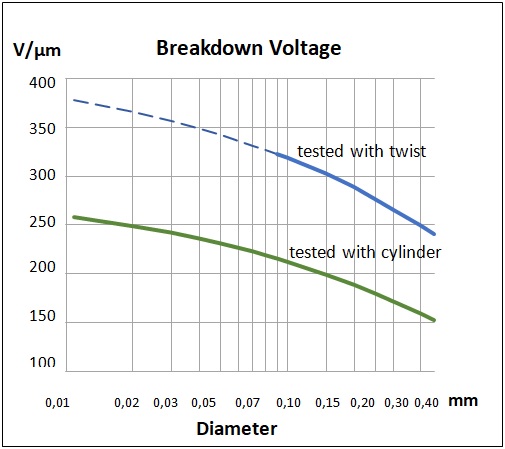

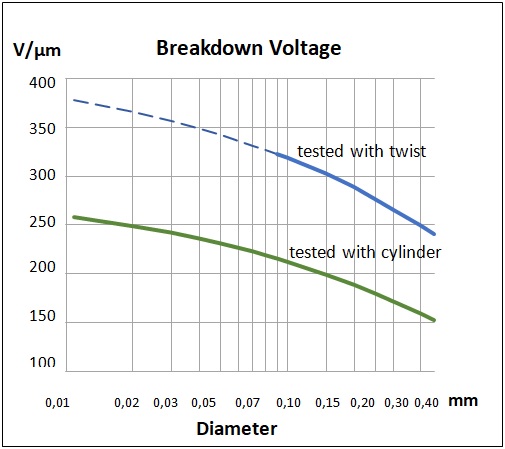

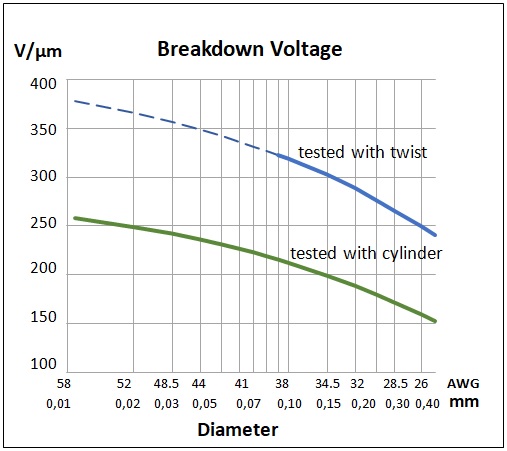

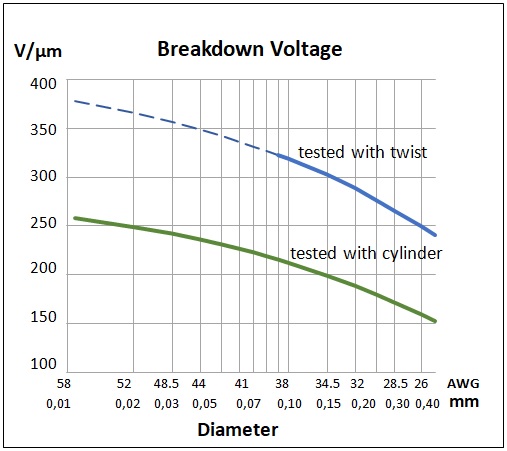

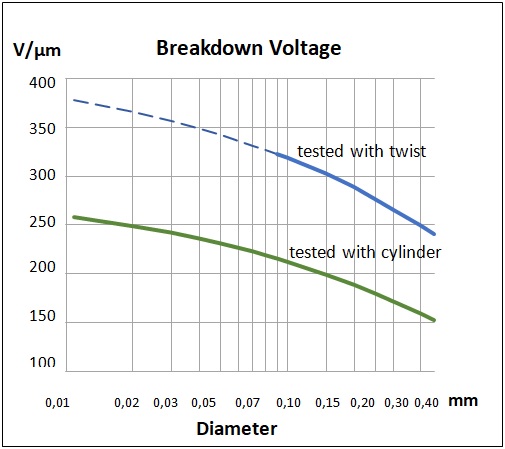

Average breakdown voltage at 20°C

|

|

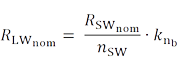

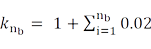

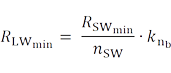

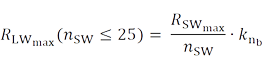

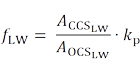

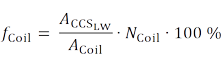

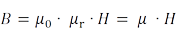

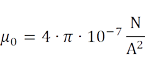

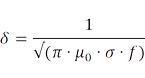

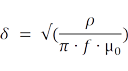

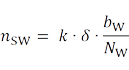

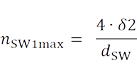

Calculation of Breakdown Voltage (Test acc. to IEC 60851-5 4.)

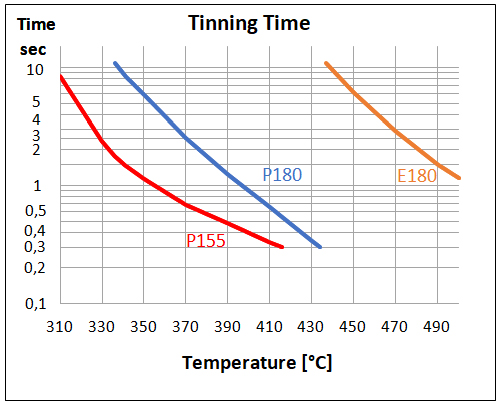

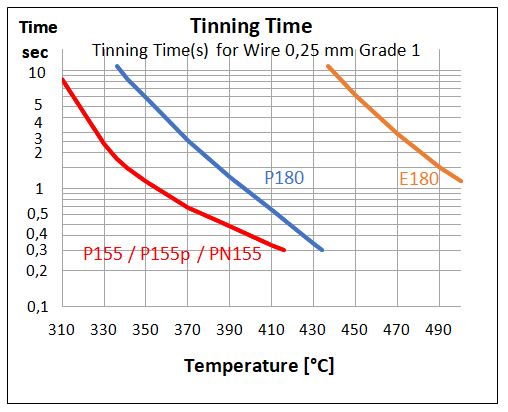

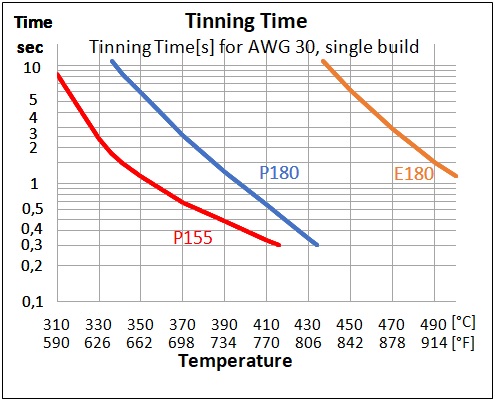

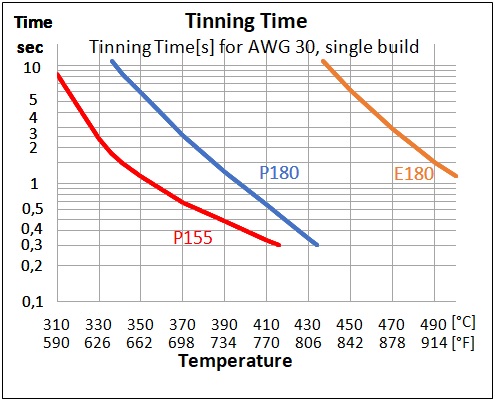

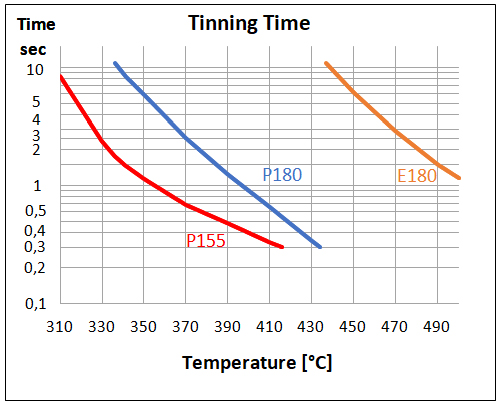

Solderability of different Wire Types

Tinning time [sec] for wire 0.25mm Grade 1 vs. Tin bath temp. [°C]

|

Product Code

|

P155 |

P180 |

G180 |

E180 |

A200 |

AI210 |

I220

|

ML240

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Polysol© 155 | Polysol© 180 | Estersol© 180 | Amidester© 200 | Amidester© 210 | |||

| General Description | mod. Polyurethane | mod. Polyurethane | mod. Polyurethane | Polyesterimide | Theic-mod. Polyesterimide | A200 + Polyamidimide | Polyamidimide | aromatic Polyimide |

| IEC (including the following standards) |

IEC 60317-20, IEC 60317-4 |

IEC 60317-51, IEC 60317-20 |

IEC 60317-51, IEC 60317-20 |

IEC 60317-23, IEC 60317-3, IEC 60317-8 |

IEC 60317-84, IEC 60317-8 |

IEC 60317-13 |

IEC 60317-57, IEC 60317-26 |

IEC 60317-46, IEC 60317-7 |

| NEMA (including the following standards) | MW 79, MW 2, MW 75 | MW 82, MW 79, MW 75 | MW 82, MW 79, MW 75 | MW 77, MW 5, MW 30 | MW 74, MW 5, MW 30 | MW 35, MW 73 | MW 81 | MW 16 |

| UL-approval | yes | yes | yes | yes | yes | yes | yes | yes |

| Diameters available | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm |

| Properties | Very good solderability and high thermal properties. | Good solderability at 370°C and elevated thermal values. | Lubricant free, very low outgassing, good solderability at 370°C and elevated thermal values. | Solderable at high temperatures, high thermal properties and good chemical resistance. | Very high thermal properties and good chemical resistance. | Very high thermal properties and high mechanical resistance. | High thermal properties, good chemical resistance. | Excellent thermal properties, excellent chemical and high radiation resistance. |

| Applications | Small transformers, relays, solenoids, small motors, watch coils, transformers, instruments. | Automotive coils as relays and ignition coils, transformers and solenoids. | Closed relays and SMD components. | Small motors, small transformers, automotive coils. | Motors, small motors, transformers. | Motors, transformers. | Small motors, automotive sensors and solenoids, transformers. | Extreme loads and space applications. |

| Thermal values | ||||||||

| Temperature index 20.000 h acc. to IEC 60172 | 158°C | 192°C | 192°C | 195°C | 210°C | 212°C | 230°C | 245°C |

| Thermal stability chart [view] | ||||||||

| Cut through temperature | ||||||||

| 0.05mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 230°C | ≥ 230°C | ≥ 265°C | ≥ 320°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 225°C | 260°C | 260°C | 315°C | 350°C | 365°C | 390°C | 450°C |

| 0.25mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 230°C | ≥ 230°C | ≥ 265°C | ≥ 320°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 230°C | 265°C | 265°C | 325°C | 360°C | 380°C | 410°C | 500°C |

| Heat Shock | ||||||||

| 0.05mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 260°C |

| Elektrisola typical value | 190°C | 210°C | 210°C | 260°C | 230°C | 250°C | 250°C | 330°C |

| 0.25mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 260°C |

| Elektrisola typical value | 180°C | 200°C | 200°C | 250°C | 220°C | 240°C | 240°C | 320°C |

| Electrical values | ||||||||

| Low voltage continuity for Grade 1 wires | ||||||||

| 0.05mm: acc. to IEC 60851-5 1 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 |

| Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity for Grade 1 wires | ||||||||

| 0.05mm: Elektrisola typical value | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.25mm: acc. to IEC 60851-5 2 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| 0.25mm: Elektrisola typical value | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Breakdown voltage acc. to IEC 60851-5 4 (at 20 °C, 35% humidity) | ||||||||

| 0.05mm: Elektrisola typical value | 220 V/µm | 220 V/µm | 220 V/µm | 220 V/µm | 220 V/µm | 210 V/µm | 210 V/µm | 210 V/µm |

| 0.25mm: Elektrisola typical value | 180 V/µm | 180 V/µm | 180 V/µm | 180 V/µm | 180 V/µm | 170 V/µm | 170 V/µm | 170 V/µm |

| Calculation method of break voltage [view] | ||||||||

| Decrease of breakdown voltage at elevated temperature for Grade 1 wires | ||||||||

| 0.05mm: Elektrisola typical value | 25% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 200°C | 20% / 220°C | 20% / 220°C | 15% / 240°C |

| 0.25mm: Elektrisola typical value | 25% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 200°C | 20% / 220°C | 15% / 240°C |

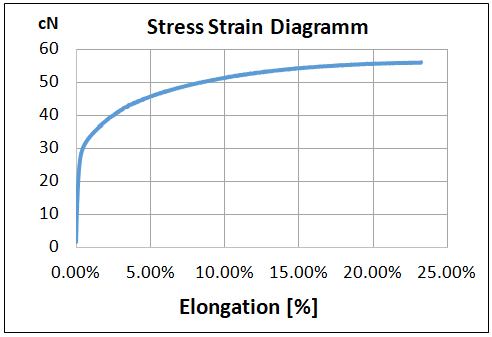

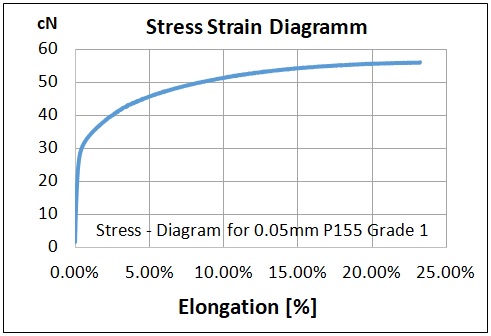

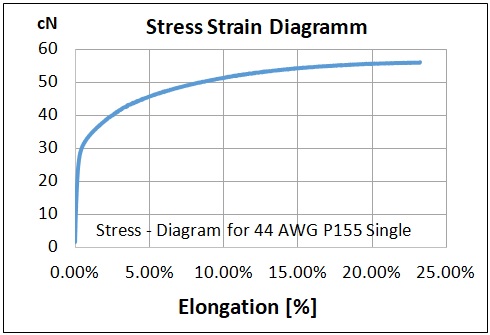

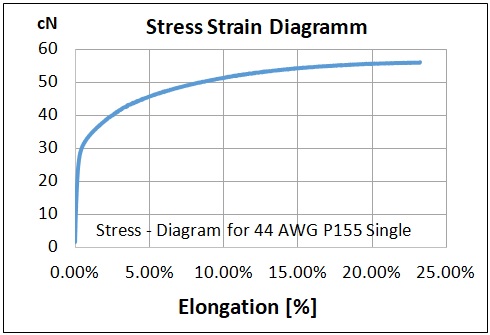

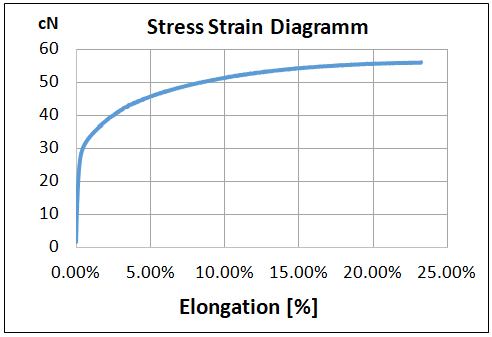

| Mechanical values | ||||||||

| Elongation for Grade 1 wire | ||||||||

| 0.05mm: acc. to IEC 60851-3 Part 3 1 | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% |

| 0.05mm: Elektrisola typical value | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% |

| 0.25mm: acc. to IEC 60851-3 Part 3 1 | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% |

| 0.25mm: Elektrisola typical value | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

| Tensile strength for Grade 1 wires | ||||||||

| 0.05mm: Elektrisola typical value | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN |

| 0.25mm: Elektrisola typical value | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN |

| Stress strain chart [view] | ||||||||

| Chemical compatibility | ||||||||

| Compatibility to standard solution | ||||||||

| Pencil Hardness acc. to IEC 60851-4 3 without treatment | ≥ H | ≥ H | ≥ H | ≥ H | ≥ H | ≥ H | ≥ H | ≥ H |

| Pencil Hardness acc. to IEC 60851-4 3 with treatment | ≥ H | ≥ H | ≥ H | ≥ H | ≥ 2B | ≥ H | ≥ H | ≥ HB |

| Decrease of breakdown voltage in % after treatment | 5% | 0% | 0% | 0% | 5% | 0% | 5% | 0% |

| RoHS laboratory analysis | view | view | view | view | view | view | view | |

| Solderablity | ||||||||

| Solderability for Grade 1 wires | ||||||||

| 0.05mm: max. acc. to IEC 60851-4 5 | 2.0s / 390°C | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.3s / 370°C | 1.8s / 370°C | 1.8s / 370°C | 1.8s / 470°C | ||||

| Elektrisola typical value | 0.2s / 390°C | 0.7s / 390°C | 0.7s / 390°C | |||||

| 0.25mm: max. acc. to IEC 60851-4 5 | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.7s / 370°C | 2.8s / 370°C | 2.8s / 370°C | 2.8s / 470°C | ||||

| Elektrisola typical value | 0.5s / 390°C | 1.1s / 390°C | 1.1s / 390°C | |||||

| Solderability of different wire types chart [view] |

Asia

Enamelled Copper Wires acc. to IEC-Asia

IEC 60317 specifies different enamelled wire types. Test methods referred to are IEC 60851, which are also partially adopted by JIS.

Thermal Stability acc. to IEC 60172

The line chart below is for technical comparison only and cannot be used to forecast lifetime of wound products (see also IEC 60172)

Thermal Stability in Hours [h] vs. Temperature in Degrees Celsius [°C]

Average breakdown voltage at 20°C

|

|

Calculation of Breakdown Voltage (Test acc. to IEC 60851.5.4.2, cylinder) The Breakdown voltage depends mainly on the thickness of the insulation (see formula), but also on the bare wire diameter, the application temperature of the coil and the type of enamel.

Solderability of different Wire Types

Tinning time [sec] for wire 0.25mm Grade 1 vs. Tin bath temp. [°C]

|

Product Code

|

P155

|

PN155

|

P155p

|

P180

|

E180

|

A200

|

AI210

|

I220

|

ML240

|

|---|---|---|---|---|---|---|---|---|---|

| Product-Name | Polysol© 155 | Polysol-N© 155 | Polysol© 155p | Polysol© 180 | Estersol© 180 | Amidester© 200 | Amidester© 210 | ||

| General Description | mod. Polyurethane | mod. Polyurethane/ Polyamide overcoat | mod. Polyurethane | mod. Polyurethane | Polyesterimide | Theic-mod. Polyesterimide | A200 + Polyamidimide | Polyamidimide | aromatic Polyimide |

| IEC (including the following norms) | IEC 60317-20, IEC 60317-4 | IEC 60317-21, IEC 60317-19 | IEC 60317-20, IEC 60317-4 | IEC 60317-51, IEC 60317-20 | IEC 60317-23, IEC 60317-3, IEC 60317-8 | IEC 60317-84, IEC 60317-8 |

IEC 60317-13 | IEC 60317-57, IEC 60317-26 | IEC 60317-46, IEC 60317-7 |

| NEMA (including the following norms) | MW 79, MW 2, MW 75 | MW 80, MW 28 | MW 79, MW 2, MW 75 | MW 82, MW 79, MW 75 | MW 77, MW 5, MW 30 | MW 74, MW 5, MW 30 | MW 35, MW 73 | MW 81 | MW 16 |

| UL-approval | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Diameters available | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.015 - 0.50 mm | 0.020 - 0.50 mm | 0.015 - 0.50 mm, ex USA |

| Properties | Very good solderability and high thermal properties. | Very good solderability with high thermal properties. | Very good solderability and high thermal properties, no elongation pinholes. | Good solderability at 370°C and elevated thermal values. | Solderable at high temperatures, high thermal properties and good chemical resistance. | Very high thermal properties and good chemical resistance. | Very high thermal properties and high mechanical resistance. | High thermal properties, good chemical resistance. | Excellent thermal properties, excellent chemical and high radiation resistance. |

| Applications | Small transformers, relays, solenoids, small motors, watch coils, transformers, instruments. | Appliance motors, encapsulated coils, solenoids, transformers, toroids. | Small transformers, timers, relays, small motors, solenoids, clock coils, watch coils, magnetic heads. | Automotive coils as relays and ignition coils, transformers and solenoids. | Small motors, small transformers, automotive coils. | Motors, small motors, transformers. | Motors, transformers. | Small motors, automotive sensors and solenoids, transformers. | Extreme loads and space applications. |

| Thermal values | |||||||||

| Temperature index 20.000 h acc. to IEC 60172 | 158°C | 158°C | 164°C | 192°C | 195°C | 210°C | 212°C | 230°C | 245°C |

| Thermal stability chart [view] | |||||||||

| Cut through temperature | |||||||||

| 0.05mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 200°C | ≥ 200°C | ≥ 230°C | ≥ 265°C | ≥ 320°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 225°C | 225°C | 225°C | 260°C | 315°C | 350°C | 365°C | 390°C | 450°C |

| 0.25mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 200°C | ≥ 200°C | ≥ 230°C | ≥ 265°C | ≥ 320°C | ≥ 350°C | ≥ 450°C | |

| Elektrisola typical value | 230°C | 230°C | 230°C | 265°C | 325°C | 360°C | 380°C | 410°C | 450°C |

| Heat Shock | |||||||||

| 0.05mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 260°C |

| Elektrisola typical value | 190°C | 190°C | 190°C | 210°C | 260°C | 230°C | 250°C | 250°C | 300°C |

| 0.25mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 260°C |

| Elektrisola typical value | 180°C | 180°C | 180°C | 200°C | 250°C | 220°C | 240°C | 240°C | 300°C |

| Electrical values | |||||||||

| Low voltage continuity for Grade 1 wires | |||||||||

| 0.05mm: acc. to IEC 60851-5 1 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 |

| Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity for Grade 1 wires | |||||||||

| 0.05mm: Elektrisola typical value | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.25mm: acc. to IEC 60851-5 2 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| Elektrisola typical value | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Pinholes acc. to JIS C3003.6c | |||||||||

| with 0% elongation | good | good | very good | very good | very good | very good | very good | very good | very good |

| with 3% elongation | not good | not good | very good | very good | very good | good | very good | very good | very good |

| Breakdown voltage acc. to IEC 60851-5 4 (at 20 ?, 35% humidity) | |||||||||

| 0.05mm: Elektrisola typical value | 220 V/µm | 210 V/µm | 220 V/µm | 220 V/µm | 220 V/µm | 220 V/µm | 210 V/µm | 210 V/µm | 210 V/µm |

| 0.25mm: Elektrisola typical value | 180 V/µm | 150 V/µm | 180 V/µm | 180 V/µm | 180 V/µm | 180 V/µm | 170 V/µm | 170 V/µm | 170 V/µm |

| Decrease of breakdown voltage for Grade 1 wires | |||||||||

| 0.05mm: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C | |

| 0.25mm: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 25% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C |

| Calculation method of break voltage [view] | |||||||||

| Mechanical values | |||||||||

| Elongation for Grade 1 wire | |||||||||

| 0.05mm: acc. to IEC 60851-3 Part 3 1 | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% |

| Elektrisola typical value | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% |

| 0.25mm: acc. to IEC 60851-3 Part 3 1 | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% |

| Elektrisola typical value | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

| Tensile strength for Grade 1 wires | |||||||||

| 0.05mm: Elektrisola typical value | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN |

| 0.25mm: Elektrisola typical value | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN |

| Stress strain chart [view] | |||||||||

| Chemical compatibility | |||||||||

| Compatibility to standard solution | |||||||||

| Pencil Hardness acc. to IEC 60851-4 3 with treatment | 4H | 4H | 4H | 4H | 4H | 4H | 4H | 4H | 6H |

| Pencil Hardness acc. to IEC 60851-4 3 without treatment | 4H | 4H | 4H | 4H | 4H | 4H | 4H | 4H | 6H |

| Decrease of breakdown voltage in % after treatment | 5% | 5% | 5% | 0% | 0% | 5% | 0% | 5% | 0% |

| RoHS laboratory analysis | view | view | view | view | view | view | view | ||

| Solderability | |||||||||

| Solderability for Grade 1 wires | |||||||||

| 0.05mm: max. acc. to IEC 60851-4 5 | 2.0s / 390°C | 2.0s / 390°C | 2.0s / 390°C | 3.0s / 390°C | 3.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.3s / 370°C | 0.3s / 370°C | 0.3s / 370°C | 1.8s / 370°C | 1.8s / 470°C | ||||

| Elektrisola typical value | 0.2s / 390°C | 0.2s / 390°C | 0.2s / 390°C | 0.7s / 390°C | |||||

| 0.25mm: max. acc. to IEC 60851-4 5 | 2.0s / 390°C | 2.0s / 390°C | 2.0s / 390°C | 3.0s / 390°C | 3.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.7s / 370°C | 0.7s / 370°C | 0.7s / 370°C | 2.8s / 370°C | 2.8s / 470°C | ||||

| Elektrisola typical value | 0.5s / 390°C | 0.5s / 390°C | 0.5s / 390°C | 1.1s / 390°C | |||||

| Solderability of different wire types chart [view] |

America (inch)

Copper Magnet Wire acc. to NEMA MW 1000C (inch)

Thermal Stability acc. to IEC 60172

The line chart below is for technical comparison only and cannot be used to forecast lifetime of wound products (see also ASTM D2307)

Thermal Stability in Hours [h] vs. Temperature in Degrees Celsius [°C] or Fahrenheit [°F]

Average breakdown voltage at 20°C

|

|

Calculation of Breakdown Voltage (Test acc. to IEC 60851.5.4.2, cylinder)

Solderability of different Wire Types

|

Product Code

|

P155

|

PN155

|

P180

|

E180

|

A200

|

AI210

|

I220

|

ML240

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Polysol© 155 | Polysol-N© 155 | Polysol© 180 | Estersol© 180 | Amidester© 200 | Amidester© 210 | ||

| General Description | mod. Polyurethane | mod. Polyurethane/ Polyamide overcoat | mod. Polyurethane | Polyesterimide | Theic-mod. Polyesterimide | A200 + Polyamidimide | Polyamidimide | aromatic Polyimide |

| NEMA (including the following norms) | MW 79, MW 2, MW 75 | MW 80, MW 28 | MW 82, MW 79, MW 75 | MW 77, MW 5, MW 30 | MW 74, MW 5, MW 30 | MW 35, MW 73 | MW 81 | MW 16 |

| IEC (including the following norms) | IEC 60317-20, IEC 60317-4 | IEC 60317-21, IEC 60317-19 | IEC 60317-51, IEC 60317-20 | IEC 60317-23, IEC 60317-3/8 | IEC 60317-84, IEC 60317-8 |

IEC 60317-13 | IEC 60317-57, IEC 60317-26 | IEC 60317-46, IEC 60317-7 |

| UL-approval | yes | yes | yes | yes | yes | yes | yes | yes |

| Diameters available | 56 - 24 AWG | 56 - 24 AWG | 56 - 24 AWG | 56 - 24 AWG | 56 - 24 AWG | 56 - 24 AWG | 52 - 24 AWG | 56 - 24 AWG |

| Properties | Very good solderability and high thermal properties. | Very good solderability with high thermal properties. | Good solderability at 370°C and elevated thermal values. | Solderable at high temperatures, high thermal properties and good chemical resistance. | Very high thermal properties and good chemical resistance. | Very high thermal properties and high mechanical resistance. | High thermal properties, good chemical resistance. | Excellent thermal properties, excellent chemical and high radiation resistance. |

| Applications | Small transformers, relays, solenoids, small motors, watch coils, transformers, instruments. | Appliance motors, encapsulated coils, solenoids, transformers, toroids. | Automotive coils as relays and ignition coils, transformers and solenoids. | Small motors, small transformers, automotive coils. | Motors, small motors, transformers. | Motors, transformers. | Small motors, automotive sensors and solenoids, transformers. | Extreme loads and space applications. |

| Thermal values | ||||||||

| Temperature index 20,000 h acc. to ASTM D 2307 | 158°C | 170°C | 192°C | 195°C | 210°C | 212°C | 230°C | 245°C |

| Thermal stability chart [view] | ||||||||

| Cut through temperature | ||||||||

| 44 AWG: acc. to NEMA MW1000, 3.50 | ≥ 200°C | ≥ 200°C | ≥ 225°C | ≥ 225°C | ≥ 300°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 225°C | 225°C | 260°C | 315°C | 350°C | 365°C | 390°C | 480°C |

| 30 AWG: acc. to NEMA MW1000, 3.50 | ≥ 200°C | ≥ 200°C | ≥ 225°C | ≥ 225°C | ≥ 300°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 230°C | 230°C | 265°C | 325°C | 360°C | 380°C | 410°C | 480°C |

| Heat Shock | ||||||||

| 44 AWG: acc. to NEMA MW1000, 3.5 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 280°C |

| Elektrisola typical value | 190°C | 190°C | 210°C | 260°C | 230°C | 230°C | 250°C | 300°C |

| 30 AWG: acc. to NEMA MW1000, 3.5 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 280°C |

| Elektrisola typical value | 180°C | 180°C | 200°C | 250°C | 220°C | 220°C | 240°C | 300°C |

| Electrical values | ||||||||

| Low voltage continuity acc. to NEMA MW 1000, 3.9.3 | ||||||||

| 44 AWG single: acc. to NEMA MW 1000, 3.9.3 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 | ≤ 25 |

| Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity acc. to NEMA MW 1000, 3.9.2 | ||||||||

| 44 AWG single: acc. to NEMA MW 1000, 3.9.2 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Elektrisola typical value | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 30 AWG single: acc. to NEMA MW 1000, 3.9.2 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Elektrisola typical value | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Breakdown voltage (at 20° C, 35% humidity) acc. to NEMA MW1000, 3.8.7 | ||||||||

| 44 AWG single: Elektrisola typical value | 9000 V/mil | 8700 V/mil | 9000 V/mil | 9000 V/mil | 9000 V/mil | 8700 V/mil | 8700 V/mil | 8700 V/mil |

| 30 AWG single: Elektrisola typical value | 6000 V/mil | 5800 V/mil | 6000 V/mil | 6000 V/mil | 6000 V/mil | 5800 V/mil | 5800 V/mil | |

| Decrease of breakdown voltage in % at elevated temperature, Elektrisola typical value for 44/30AWG, Single build | ||||||||

| 44 AWG single: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C |

| 30 AWG single: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C |

| Calculation method of break voltage [view] | ||||||||

| Mechanical values | ||||||||

| Elongation min. acc. to NEMA MW 1000, 3.4 for 44/30 AWG | ||||||||

| 44 AWG: acc. to NEMA MW 1000, 3.4 | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% |

| Elektrisola typical value | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% |

| 30 AWG: acc. to NEMA MW 1000, 3.4 | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% |

| Elektrisola typical value | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

| Tensile strength for Grade 1 wires | ||||||||

| 44 AWG: Elektrisola typical value | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN |

| 30 AWG: Elektrisola typical value | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN |

| Stress strain chart [view] | ||||||||

| Chemical compatibility | ||||||||

| Solubility per NEMA MW 1000, 3.51.1.1.3 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

| Compatibility to standard solution | ||||||||

| Decrease of breakdown voltage in % after treatment | 5% | 5% | 5% | 5% | 5% | 0% | 0% | 5% |

| RoHS laboratory analysis | view | view | view | view | view | view | ||

| Solderability | ||||||||

| Solderability acc. to. NEMA MW 1000 3.13.1.1 max. seconds at °C for 44/30 AWG | ||||||||

| 44 AWG: acc. to NEMA MW 1000 3.13 | 2.5s / 390°C | 2.5s / 390°C | 2.5s / 390°C | 4.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.3s / 370°C | 0.3s / 370°C | 1.5s / 370°C | 1.8s / 470°C | ||||

| Elektrisola typical value | 0.2s / 390°C | 0.2s / 390°C | 0.7s / 390°C | |||||

| 30 AWG: acc. to NEMA MW 1000 3.13 | 3.5s / 390°C | 3.5s / 390°C | 3.5s / 390°C | 5.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.7s / 370°C | 0.7s / 370°C | 2.8s / 370°C | 2.8s / 470°C | ||||

| Elektrisola typical value | 0.5s / 390°C | 0.5s / 390°C | 1.1s / 390°C | |||||

| Solderability of different wire types chart [view] |

America (metric)

Copper Magnet Wire acc. to NEMA MW 1000C (metric)

Thermal Stability acc. to IEC 60172

The line chart below is for technical comparison only and cannot be used to forecast lifetime of wound products (see also ASTM D2307)

Thermal Stability in Hours [h] vs. Temperature in Degrees Celsius [°C] or Fahrenheit [°F]

Average breakdown voltage at 20°C

|

|

Calculation of Breakdown Voltage (Test acc. to IEC 60851.5.4.2, cylinder)

Solderability of different Wire Types

|

Product Code

|

P155

|

PN155

|

P180

|

E180

|

A200

|

AI210

|

I220

|

ML240

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Polysol© 155 | Polysol-N© 155 | Polysol© 180 | Estersol© 180 | Amidester© 200 | Amidester© 210 | ||

| General Description | mod. Polyurethane | mod. Polyurethane/ Polyamide overcoat | mod. Polyurethane | Polyesterimide | Theic-mod. Polyesterimide | A200 + Polyamidimide | Polyamidimide | aromatic Polyimide |

| NEMA (including the following norms) | MW 79, MW 2, MW 75 | MW 80, MW 28 | MW 82, MW 79, MW 75 | MW 77, MW 5, MW 30 | MW 74, MW 5, MW 30 | MW 35, MW 73 | MW 81 | MW 16 |

| IEC (including the following norms) | IEC 60317-20, IEC 60317-4 | IEC 60317-21, IEC 60317-19 | IEC 60317-51, IEC 60317-20 | IEC 60317-23, IEC 60317-3/8 | IEC 60317-84, IEC 60317-8 |

IEC 60317-13 | IEC 60317-57, IEC 60317-26 | IEC 60317-46, IEC 60317-7 |

| UL-approval | yes | yes | yes | yes | yes | yes | yes | yes |

| Diameters available | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.015 - 0.50 mm | 0.020 - 0.50 mm | 0.015 - 0.50 mm, ex USA |

| Properties | Very good solderability and high thermal properties. | Very good solderability with high thermal properties. | Good solderability at 370°C and elevated thermal values. | Solderable at high temperatures, high thermal properties and good chemical resistance. | Very high thermal properties and good chemical resistance. | Very high thermal properties and high mechanical resistance. | High thermal properties, good chemical resistance. | Excellent thermal properties, excellent chemical and high radiation resistance. |

| Applications | Small transformers, relays, solenoids, small motors, watch coils, transformers, instruments. | Appliance motors, encapsulated coils, solenoids, transformers, toroids. | Automotive coils as relays and ignition coils, transformers and solenoids. | Small motors, small transformers, automotive coils. | Motors, small motors, transformers. | Motors, transformers. | Small motors, automotive sensors and solenoids, transformers. | Extreme loads and space applications. |

| Thermal values | ||||||||

| Temperature index 20,000 h acc. to ASTM D 2307 | 158°C | 158°C | 192°C | 195°C | 210°C | 212°C | 230°C | 245°C |

| Thermal stability chart [view] | ||||||||

| Cut through temperature | ||||||||

| 44 AWG: acc. to NEMA MW1000, 3.50 | ≥ 200°C | ≥ 200°C | ≥ 225°C | ≥ 225°C | ≥ 300°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 225°C | 225°C | 260°C | 315°C | 350°C | 365°C | 390°C | 480°C |

| 30 AWG: acc. to NEMA MW1000, 3.50 | ≥ 200°C | ≥ 200°C | ≥ 225°C | ≥ 225°C | ≥ 300°C | ≥ 320°C | ≥ 350°C | ≥ 450°C |

| Elektrisola typical value | 230°C | 230°C | 265°C | 325°C | 360°C | 380°C | 410°C | 480°C |

| Heat Shock | ||||||||

| 44 AWG: acc. to NEMA MW1000, 3.5 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 280°C |

| Elektrisola typical value | 190°C | 190°C | 210°C | 260°C | 230°C | 230°C | 250°C | 300°C |

| 30 AWG: acc. to NEMA MW1000, 3.5 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 240°C | ≥ 250°C |

| Elektrisola typical value | 180°C | 180°C | 200°C | 250°C | 220°C | 220°C | 240°C | 300°C |

| Electrical values | ||||||||

| Low voltage continuity acc. to NEMA MW 1000, 3.9.3 | ||||||||

| 44 AWG single: acc. to NEMA MW 1000, 3.9.3 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity acc. to NEMA MW 1000, 3.9.2 | ||||||||

| 44 AWG single: acc. to NEMA MW 1000, 3.9.2 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Elektrisola typical value | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 30 AWG single: acc. to NEMA MW1000, 3.9.2 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Elektrisola typical value | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Breakdown voltage (at 20° C, 35% humidity) acc. to NEMA MW1000, 3.8.7 | ||||||||

| 44 AWG single: Elektrisola typical value | 9000 V/mil | 8700 V/mil | 9000 V/mil | 9000 V/mil | 9000 V/mil | 8700 V/mil | 8700 V/mil | 8700 V/mil |

| 30 AWG single: Elektrisola typical value | 6000 V/mil | 5800 V/mil | 6000 V/mil | 6000 V/mil | 6000 V/mil | 5800 V/mil | 5800 V/mil | |

| Decrease of breakdown voltage in % at elevated temperature, Elektrisola typical value for 44/30AWG, Single build | ||||||||

| 44 AWG single: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C |

| 30 AWG single: Elektrisola typical value | 25% / 155°C | 30% / 155°C | 20% / 180°C | 20% / 180°C | 20% / 200°C | 20% / 205°C | 20% / 205°C | 15% / 220°C |

| Calculation method of break voltage [view] | ||||||||

| Mechanical values | ||||||||

| Elongation min. acc. to NEMA MW 1000, 3.4 for 44/30 AWG | ||||||||

| 44 AWG: acc. to NEMA MW 1000, 3.4 | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% |

| Elektrisola typical value | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% |

| 30 AWG: acc. to NEMA MW 1000, 3.4 | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% |

| Elektrisola typical value | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

| Tensile strength for Grade 1 wires | ||||||||

| 44 AWG: Elektrisola typical value | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN |

| 30 AWG: Elektrisola typical value | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN |

| Stress strain chart [view] | ||||||||

| Chemical compatibility | ||||||||

| Solubility per NEMA MW 1000, 3.51.1.1.3 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

| Compatibility to standard solution | ||||||||

| Decrease of breakdown voltage in % after treatment | 5% | 5% | 0% | 0% | 5% | 0% | 5% | 0% |

| RoHS laboratory analysis | view | view | view | view | view | view | ||

| Solderability | ||||||||

| Solderability acc. to. NEMA MW 1000 3.13.1.1 max. seconds at °C for 44/30 AWG | ||||||||

| 44 AWG: acc. to NEMA MW 1000 3.13 | 4.0s / 390°C | 4.0s / 390°C | 4.0s / 390°C | 4.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.3s / 370°C | 0.3s / 370°C | 1.5s / 370°C | 1.8s / 470°C | ||||

| Elektrisola typical value | 0.2s / 390°C | 0.2s / 390°C | 0.7s / 390°C | |||||

| 30 AWG: acc. to NEMA MW 1000 3.13 | 5.0s / 390°C | 5.0s / 390°C | 5.0s / 390°C | 5.0s / 470°C | not solderable | not solderable | not solderable | not solderable |

| Elektrisola typical value | 0.7s / 370°C | 0.7s / 370°C | 2.8s / 370°C | 2.8s / 470°C | ||||

| Elektrisola typical value | 0.5s / 390°C | 0.5s / 390°C | 1.1s / 390°C | |||||

| Solderability of different wire types chart [view] |

SB Technical Data

Self Bonding Technical Data

Europe / Asia IEC 60317

Technical Data for Selfbonding Copper Wire by Size acc. to IEC 60317

| Minimum coat thickness and maximum overall diameter | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conductor (Bare Wire) |

Grade 1B | Grade 2B | Elongation acc to IEC |

Resistance at 20 °C | Breakdown Voltage acc to IEC ** |

1 kg of enamelled wire length approx. | Filling Factor number of enamelled wires/cm² |

Tension | |||||||||||

| Nominal Diameter | Tolerance | Section | min inc. base coat |

min inc. bond coat |

max o.d. | min inc. base coat |

min inc. bond coat |

max o.d. | min | nom | min | max | Grade 1B | Grade 2B | Grade 1B | Grade 2B | Grade 1B | Grade 2B | max |

| [mm] | [mm] | [mm²] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [%] | [Ohm/m] | [Ohm/m] | [Ohm/m] | min. [V] | min. [V] | [km] | [km] | [n] | [n] | [cN] |

| 0.010 | * | 0.000078540 | 0.0013 | 0.0008 | 0.0133 | 3 | 217.65 | 195.88 | 239.41 | 70 | 125 | 1306 | 715995 | 1.4 | |||||

| 0.012 | * | 0.000113097 | 0.0013 | 0.0008 | 0.0160 | 3 | 151.14 | 136.03 | 166.26 | 80 | 150 | 912.3 | 509852 | 2.0 | |||||

| 0.014 | * | 0.000153938 | 0.0016 | 0.0010 | 0.0190 | 4 | 111.04 | 99.94 | 122.15 | 90 | 175 | 666.3 | 364483 | 2.5 | |||||

| 0.016 | * | 0.000201062 | 0.0016 | 0.001 | 0.022 | 0.004 | 0.001 | 0.025 | 5 | 85.02 | 76.52 | 93.52 | 100 | 200 | 510.6 | 477.3 | 280237 | 212719 | 3.2 |

| 0.018 | * | 0.000254469 | 0.0018 | 0.001 | 0.024 | 0.004 | 0.001 | 0.027 | 5 | 67.18 | 60.46 | 73.89 | 110 | 225 | 406.8 | 384.2 | 230156 | 180417 | 3.9 |

| 0.019 | * | 0.000283529 | 0.0019 | 0.001 | 0.025 | 0.004 | 0.001 | 0.028 | 6 | 60.29 | 54.26 | 66.32 | 115 | 240 | 366.4 | 347.5 | 210006 | 166957 | 4.3 |

| 0.020 | * | 0.000314159 | 0.002 | 0.002 | 0.026 | 0.004 | 0.002 | 0.029 | 6 | 54.41 | 48.97 | 59.85 | 120 | 250 | 328.9 | 314.7 | 184773 | 152705 | 4.7 |

| 0.021 | * | 0.000346361 | 0.002 | 0.002 | 0.029 | 0.004 | 0.002 | 0.031 | 6 | 49.35 | 44.42 | 54.29 | 125 | 265 | 294.7 | 284.8 | 158413 | 137316 | 5.1 |

| 0.022 | * | 0.000380133 | 0.002 | 0.002 | 0.030 | 0.005 | 0.002 | 0.033 | 6 | 44.97 | 40.47 | 49.47 | 130 | 275 | 269.7 | 256.9 | 147300 | 120169 | 5.5 |

| 0.023 | * | 0.000415476 | 0.002 | 0.002 | 0.031 | 0.005 | 0.002 | 0.034 | 7 | 41.14 | 37.03 | 45.26 | 145 | 290 | 247.8 | 236.6 | 137316 | 112776 | 6.0 |

| 0.024 | * | 0.000452389 | 0.002 | 0.002 | 0.032 | 0.005 | 0.002 | 0.035 | 7 | 37.79 | 34.01 | 41.56 | 145 | 290 | 228.4 | 218.5 | 128314 | 106045 | 6.5 |

| 0.025 | * | 0.000490874 | 0.003 | 0.002 | 0.034 | 0.005 | 0.002 | 0.037 | 7 | 34.82 | 31.34 | 38.31 | 150 | 300 | 208.3 | 201.0 | 112776 | 97024 | 7.0 |

| 0.027 | * | 0.000572555 | 0.003 | 0.002 | 0.037 | 0.005 | 0.002 | 0.040 | 7 | 29.86 | 26.87 | 32.84 | 165 | 315 | 178.7 | 173.0 | 97024 | 84356 | 8.0 |

| 0.028 | * | 0.000615752 | 0.003 | 0.003 | 0.038 | 0.006 | 0.003 | 0.042 | 7 | 27.76 | 24.99 | 30.54 | 170 | 325 | 165.7 | 158.5 | 89107 | 74016 | 8.5 |