bondABLE MAGNET Wire Types

General

There is a large variety of bondable magnet wire types available. The different base coats and self bonding overcoats are described in different standards, such as IEC 60317, NEMA MW 1000 or JIS C3202, which sometimes utilize different test methods.

Under the respective standard the typical technical values are given for the different base coats such as Polyurethane, Polyester, Polyesterimide etc. and for different bond coats such as Polyvinylbutyral, Polyamide etc.

For easier comparison of products and the evaluation of their suitability for certain applications, there is a check box below each of the product-codes and a "Compare Selected Items" button in the precolumn of the table. When this button is clicked, only the marked items appear side by side. This view of the table is also suitable for printing; to use the options of your browser for this purpose, please use the "Show all" button to make the invisible products reappear again.

Europe

Bondable Magnet Wire acc. to IEC

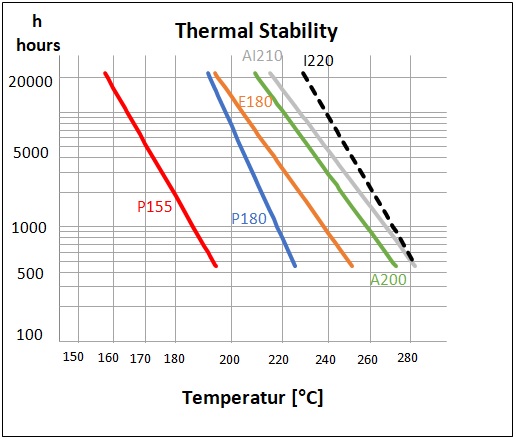

Thermal Stability acc. to IEC 60172

The line chart below is for technical comparison only and cannot be used to forecast lifetime of wound products (see also IEC 60172)

Thermal Stability in Hours [h] vs. Temperature in Degrees Celsius [°C]

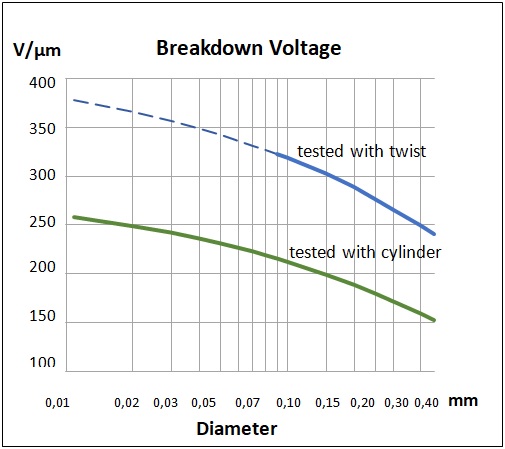

Average breakdown voltage at 20°C

|

|

Calculation of Breakdown Voltage (Test acc. to IEC 60851-5 4.)

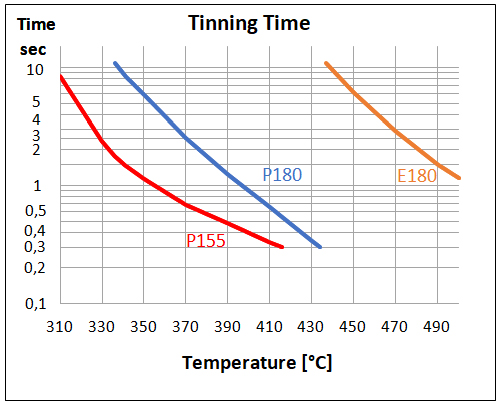

Solderability of different Wire Types

Tinning time [sec] for wire 0.25mm Grade 1 vs. Tin bath temp. [°C]

|

Product-Code

|

AB15

|

FS15

|

FSP18

|

FS18

|

PSP15

|

STP18

|

QTP18

|

RT21

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Butybond AB15 | Solabond FS15 | Solabond FSP18 | Solabond FS18 | Solabond PSP15 | Thermobond STP18 | Thermobond QTP18 | Thermobond RT21 |

| General Description | ||||||||

| Base coat | mod. Polyurethane | mod. Polyurethane | mod. Polyurethane | Polyesterimide | mod. Polyurethane | mod. Polyurethane | mod. Polyurethane | A200 + Polyamidimide |

| Bond coat | Polyvinylbutyral | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | aromatic Polyamide |

| IEC (including the following norms) | IEC 60317-35, 60317-2 | IEC 60317-35, 60317-2 | IEC 60317-36 | IEC 60317-35, 60317-2 | IEC 60317-35 | IEC 60317-38 | ||

| NEMA (including the following norms) | MW 131-C | MW 131 | MW 131 | MW 131 | MW 131 | MW 102 | ||

| Diameters available | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm |

| Properties | Low bonding temperature, wide process window, non-hygroscopic | All bonding methods applicable, good processability, hygroscopic (not suited for humid regions) | All bonding methods applicable, good processability, hygroscopic | Solvent bonding possible, high resoftening temperature, high thermal and mechanical properties of base coat, hygroscopic thus not suitable for Asia | All purpose selfbonding enamel, wide process window, high bonding strength, thermosetting applicable, non-hygroscopic | Good winding ability, thermosetting applicable | higher thermal and mechanical properties, very high resoftening temperature after thermosetting | very high thermal and mechanical properties, very high resoftening temperature |

| Shelf life in months (at 25°C / 60% rel. humidity) |

≤ 6 | ≤ 3 (hygroscopic) | ≤ 5 (hygroscopic) | ≤ 5 (hygroscopic) | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 |

| Applications | Stepping motors for quartz watches, instrument coils, voice coils, Sensors, Transponders | Loudspeakers, small motors, sensors, Transponders | Loudspeakers, small motors, sensors, Transponders | Loudspeakers, small motors, sensors, Transponders | Instrument coils, loudspeakers, vibration motors, sensors, receiver and speaker for mobile phones | High power speaker, vibration motors | high power speaker and receiver, micro speaker, high temperature applications | motors, loudspeakers |

| Thermal values of base coat | ||||||||

| Temperature index 20.000 h acc. to IEC 60172 | 158°C | 158°C | 192°C | 195°C | 158°C | 192°C | 192°C | 212°C |

| Thermal stability chart [view] | ||||||||

| Cut through temperature | ||||||||

| 0.05mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 200°C | ≥ 230°C | ≥ 265°C | ≥ 200°C | ≥ 230°C | ≥ 230°C | ≥ 320°C |

| Elektrisola typical value | 225°C | 225°C | 260°C | 315°C | 225°C | 260°C | 260°C | 365°C |

| 0.25mm: acc. to IEC 60851-6 4 | ≥ 200°C | ≥ 200°C | ≥ 230°C | ≥ 265°C | ≥ 200°C | ≥ 230°C | ≥ 230°C | ≥ 320°C |

| Elektrisola typical value | 230°C | 230°C | 265°C | 325°C | 230°C | 265°C | 265°C | 380°C |

| Heat Shock | ||||||||

| 0.05mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C |

| Elektrisola typical value | 190°C | 190°C | 210°C | 260°C | 190°C | 210°C | 210°C | 250°C |

| 0.25mm: acc. to IEC 60851-6 3 | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 220°C |

| Elektrisola typical value | 180°C | 180°C | 200°C | 250°C | 180°C | 200°C | 200°C | 240°C |

| Electrical values | ||||||||

| Low voltage continuity for Grade 1B wires | ||||||||

| 0.05mm: acc. to IEC 60851-5 1 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 |

| Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity for Grade 1B wires | ||||||||

| 0.05mm: Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.25mm: acc. to IEC 60851-5 2 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| 0.25mm: Elektrisola typical value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Breakdown voltage acc. to IEC 60851-5 4 (at 20 °C, 35% humidity) | ||||||||

| 0.05mm: Elektrisola typical value | 160 V/µm | 160 V/µm | 160 V/µm | 160 V/µm | 160 V/µm | 160 V/µm | 160 V/µm | 160 V/µm |

| 0.25mm: Elektrisola typical value | 120 V/µm | 120 V/µm | 120 V/µm | 120 V/µm | 120 V/µm | 120 V/µm | 120 V/µm | 120 V/µm |

| Calculation method of break voltage [view] | ||||||||

| Pinholes acc. to IEC 60851-5 7 | ||||||||

| with 0.05mm: 0% elongation | good | good | very good | very good | very good | very good | ||

| with 0.25mm: 0% elongation | good | good | very good | very good | very good | very good | ||

| Mechanical values | ||||||||

| Elongation for Grade 1B wire | ||||||||

| 0.05mm: acc. to IEC 60851-3 3.1 | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% | ≥ 14% |

| Elektrisola typical value | 23% | 23% | 23% | 23% | 23% | 23% | 23% | 23% |

| 0.25mm: acc. to IEC 60851-3 3.1 | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% | ≥ 25% |

| Elektrisola typical value | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

| Tensile strength for Grade 1B wires | ||||||||

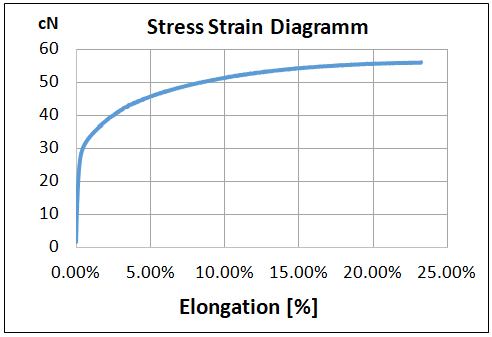

| 0.05mm: Elektrisola typical value | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN | 57 cN |

| 0.25mm: Elektrisola typical value | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN | 1370 cN |

| Stress strain chart [view] | ||||||||

| Bonding of wire | ||||||||

| Hot air bonding | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.015 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.015 – 0.50 mm | limited |

| Oven bonding | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 – 0.50 mm | 0.10 – 0.50 mm |

| Resistance bonding | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 - 0.50 mm | 0.10 – 0.50 mm | 0.10 – 0.50 mm |

| Solvent bonding | limited | suitable | suitable | suitable | not suitable | not suitable | not suitable | not suitable |

| Recommended solvent | Ethanol / Methanol | Ethanol / Methanol | Ethanol / Methanol | Ethanol / Methanol | N/A | N/A | N/A | N/A |

| Recommended bonding temperature | 120 - 140°C | 150 - 170°C | 150 - 170°C | 150 - 170°C | 150 - 170°C | 180 - 200°C | 200 – 220°C | 200 – 220°C |

| Resoftening temperature for 0.25mm (IEC 60851-3 7.1.2.4) |

≥ 100°C | ≥ 140°C | ≥ 170°C | ≥ 180°C | ≥ 180°C | ≥ 145°C | ≥ 190°C | ≥ 200°C |

| Bond strength chart | ||||||||

| RoHS laboratory analysis | view | view | view | view | view | |||

| Solderability | ||||||||

| Solderability for Grade 1B wires | ||||||||

| 0.05mm: max. acc. to IEC 60851-4 5 | 2.0s / 390°C | 2.0s / 390°C | 2.0s / 390°C | 3.0s / 470°C | 2.0s / 390°C | 3.0s / 390°C | 3.0s / 390°C | --- |

| Elektrisola typical value | 0.8s / 390°C | 0.4s / 390°C | 0.7s / 390°C | 1.3s / 470°C | 0.4s / 390°C | 0.4s / 420°C | 1.0s / 390°C | --- |

| Elektrisola typical value | 1.5s / 370°C | 0.5s / 370°C | 1.0s / 370°C | 0.7s / 370°C | --- | |||

| 0.25mm: max. acc. to IEC 60851-4 5 | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 470°C | 3.0s / 390°C | 3.0s / 390°C | 3.0s / 390°C | --- |

| Elektrisola typical value | 1.4s / 390°C | 0.7s / 390°C | 1.6s / 390°C | 3.0s / 470°C | 0.7s / 390°C | 0.8s / 420°C | 2.0s / 390°C | --- |

| Elektrisola typical value | 2.0s / 370°C | 1.2s / 370°C | 2.8s / 370°C | 1.2s / 370°C | ||||

| Solderability of different wire types chart [view] |

Asia (standard)

|

Product-Code

|

BQP15

|

CSP15

|

ES22

|

ESP15

|

KSP15

|

KSP18

|

KS18

|

KS22

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Polyesterbond BQP15 | Solabond CSP15 | Solabond ES22 | Solabond ESP15 | Solabond KSP15 | Solabond KSP18 | Solabond KS18 | Solabond KS22 |

| General Description | ||||||||

| Base coat | mod. Polyurethane | mod. Polyurethane | Polyamideimide | mod. Polyurethane | mod. Polyurethane | mod. Polyurethane | Polyesterimide | Polyamideimide |

| Bond coat | mod. Polyester | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide |

| IEC (including the following standards) | IEC 60317-35, 60317-2 | IEC 60317-35, 60317-2 | --- | IEC 60317-35, 60317-2 | IEC 60317-35, 60317-2 | IEC 60317-35 | IEC 60317-36 | --- |

| NEMA (including the following standards) | MW 131 | MW 131 | --- | MW 131 | MW 131 | --- | --- | --- |

| Diameters available | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.050 - 0.70 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.050 - 0.60 mm |

| Properties | Easy bonding, wide process window | Excellent solvent bonding, heat bonding possible | Suitable for hot air bonding, very high thermal properties of base coat | Suitable for hot air bonding, very good winding properties | Suitable for hot air bonding, excellent solderability | Suitable for hot air bonding, high thermal properties of base coat | Suitable for hot air bonding, higher thermal properties of base coat | Suitable for hot air bonding, very high thermal properties of base coat |

| Shelf life in months (at 25°C / 60% rel. humidity) |

≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| Applications | For sensors, instrument coils, RFID, transponders, card application | For voice coils, small motor, vibration motors, transponders | For molding inductor, small motor | For sensors, instrument coils, voice coils, vibration motors | For small motor, instrument coils, loudspeaker, sensors | For small motor, instrument coils, loudspeaker, sensors, transponders | For small motor, loudspeaker | For small motor, inductor |

| Thermal values of base coat | ||||||||

| Temperature index 20.000 h acc. IEC 60172 | 164°C | 164°C | 230°C | 164°C | 164°C | 192°C | 195°C | 230°C |

| Cut through temperature min. °C acc. to IEC 60851-6 4. | ≥ 200°C | ≥ 200°C | ≥ 350°C | ≥ 200°C | ≥ 200°C | ≥ 230°C | ≥ 265°C | ≥ 350°C |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 225 / 230°C | 225 / 230°C | 390 / 410°C | 225 / 230°C | 225 / 230°C | 260 / 265°C | 315 / 325°C | 390 / 410°C |

| Heat shock min. °C acc. to IEC 60851-6 3. | ≥ 175°C | ≥ 175°C | ≥ 240°C | ≥ 175°C | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 240°C |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 190 / 180°C | 190 / 180°C | 250 / 240°C | 190 / 180°C | 190 / 180°C | 210 / 200°C | 260 / 250°C | 250 / 240°C |

| Electrical values | ||||||||

| Low voltage continuity max. acc. to IEC 60851-5 5.2 for 0.05 mm | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 |

| ELEKTRISOLA-typical values for 0.05 mm, Grade 1B | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity max. acc. to IEC 60851-5 5.3 for 0.25 mm | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| ELEKTRISOLA-typical values for 0.25 mm, Grade 1B | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Breakdown voltage acc. IEC 60851-5 4., (at 20°C, 35% humidity) | ||||||||

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/µm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm |

| Mechanical values | ||||||||

| Elongation min. acc. to IEC 60851-3 3.1 for 0.05 mm/0.25 mm, Grade 1B | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% |

| Tensile strength | ||||||||

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN |

| Bonding of wire | ||||||||

| Hot air bonding | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable |

| Oven bonding | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable |

| Resistance bonding | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable | Suitable |

| Solvent bonding | Not suitable | Suitable | Not suitable | Not suitable | Not suitable | Not suitable | Not suitable | Not suitable |

| Recommended solvent | -- | Ethanol / Isopropanol | --- | --- | --- | --- | --- | --- |

| Recommended bonding temperature | 120 - 140°C | 170 - 200°C | 160 - 190°C | 160 - 190°C | 150 - 170°C | 150 - 170°C | 150 - 170°C | 150 - 170°C |

| Resoftening temperature | ≥ 90°C | ≥ 140°C | ≥ 130°C | ≥ 130°C | ≥ 105°C | ≥ 105°C | ≥ 105°C | ≥ 105°C |

| Solderability | ||||||||

| Acc. to IEC 60851-4 5. max . seconds at °C for 0.05 mm/0.25 mm, Grade 1B | 2.0s/390°C / 3.0s/390°C | 2.0s/390°C / 3.0s/390°C | 2.0s/390°C / 3.0s/390°C | 2.0s/390°C / 3.0s/390°C | 3.0s/390°C / 3.0s/390°C | 3.0s/470°C / 3.0s/470°C | Not Solderable | |

| ELEKTRISOLA-typical values IEC 60851-4 5. | ||||||||

| for 0.05 mm, Grade 1B, | 0.5s/370°C / 0.4s/390°C | 1.0s/370°C / 0.6s/390°C | --- | 1.0s/370°C / 0.6s/390°C | 0.5s/370°C / 0.4s/390°C | 1.0s/370°C / 0.7s/390°C | 1.9s/470°C | --- |

| seconds at °C | ||||||||

| for 0.25 mm, Grade 1B, | 1.2s/370°C / 0.7s/390°C | 1.6s/370°C / 0.8s/390°C | --- | 1.6s/370°C / 0.8s/390°C | 1.2s/370°C / 0.7s/390°C | 2.8s/370°C / 1.6s/390°C | 3.4s/470°C | --- |

| seconds at °C |

Asia (high performance)

|

Product-Code

|

PSP15

|

PSP18

|

STP18

|

KTP18

|

KT22

|

LTP18

|

ETP18

|

ET22

|

|---|---|---|---|---|---|---|---|---|

| Product-Name | Solabond PSP15 | Solabond PSP18 | Thermobond STP18 | Thermobond KTP18 | Thermobond KT22 | Thermobond LTP18 | Thermobond ETP18 | Thermobond ET22 |

| General Description | ||||||||

| Base coat | mod.Polyurethane | mod.Polyurethane | mod.Polyurethane | mod.Polyurethane | mod.Polyamidimide | mod.Polyurethane | mod.Polyurethane | mod.Polyamidimide |

| Bond coat | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide | Polyamide |

| IEC (including the following standards) | IEC 60317-35, 60317-2 | IEC 60317-35 | IEC 60317-35 | IEC 60317-35 | --- | IEC 60317-35 | IEC 60317-35 | --- |

| NEMA (including the following standards) | MW 131 | --- | MW 131 | --- | --- | --- | --- | --- |

| Diameters available | 0.010 - 0.50 mm | 0.010 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm |

| Properties | high resoftening temperature after thermosetting, very good properties for hot-air bonding, very good winding properties, non-hyproscopic | Thermosetting possible, high bonding strength, non-hygroscopic | Higher thermal and mechanical properties, very high resoftening temperature after thermosetting, non-hygroscopic | High resoftening temperature, suitable for High Current Test (HCT), high bonding strength, non-hygroscopic | Very High resoftening temperature, suitable for High Current Test (HCT), high bonding strength, non-hygroscopic | High resoftening temperature, suitable for High Current Test (HCT), high bonding strength, non-hygroscopic | Excellent winding performance, high resoftening temperature, high bonding strength at the coil ends, suitable for High Current Test (HCT), non-hygroscopic | Excellent winding performance, high resoftening temperature, high bonding strength at the coil ends, suitable for High Current Test (HCT), non-hygroscopic |

| Shelf life in months (at 25°C / 60% rel. humidity) |

≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| Applications | Instrument coils, loudspeakers, small motors, sensors, receiver and speaker for mobile phones | Instrument coils, loudspeakers, motors, sensors | High power speaker and receiver, micro speaker, high temperature applications | High power speaker / receiver, Micro speaker | High power speaker / receiver, Micro speaker | Loudspeakers, Stepping motors, Voice coils, Sensors, Transponders | High power speaker / receiver, Micro speaker | High power speaker / receiver, Micro speaker |

| Thermal values of base coat | ||||||||

| Temperature index 20.000 h acc. IEC 60172 | 158°C | 192°C | 192°C | 192°C | 230°C | 192°C | 192°C | 230°C |

| Cut through temperature min. °C acc. to IEC 60851-6 4. | ≥ 200°C | ≥ 230°C | ≥ 230°C | ≥ 230°C | ≥ 350°C | ≥ 230°C | ≥ 230°C | ≥ 350°C |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 225 / 230°C | 260 / 265°C | 260 / 265°C | 260 / 265°C | 390 / 410°C | 260 / 265°C | 260 / 265°C | 390 / 410°C |

| Heat shock min. °C acc. to IEC 60851-6 3. | ≥ 175°C | ≥ 200°C | ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 200°C | ≥ 200°C | ≥ 200°C |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 190 / 180°C | 210 / 200°C | 210 / 200°C | 210 / 200°C | 250 / 240°C | 210 / 200°C | 210 / 200°C | 250 / 240°C |

| Electrical values | ||||||||

| Low voltage continuity max. acc. to IEC 60851-5 5.2 for 0.05 mm Grade 1 B | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 | ≤ 40 |

| ELEKTRISOLA-typical values for 0.05 mm, Grade 1B | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High voltage continuity max. acc. to IEC 60851-5 5.3 for 0.25 mm Grade 1B | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| ELEKTRISOLA-typical values for 0.25 mm, Grade 1B | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Breakdown voltage acc. IEC 60851-5 4., (at 20°C, 35% humidity) | ||||||||

| ELEKTRISOLA-typical values test for 0.05 mm/0.25 mm, Grade 1B | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm | 160 / 120 V/μm |

| Mechanical values | ||||||||

| Elongation min. acc. to 60851-3 3.1 for 0.05 mm/0.25 mm, Grade 1B | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% |

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% |

| Tensile strength | ||||||||

| ELEKTRISOLA-typical values for 0.05 mm/0.25 mm, Grade 1B | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN | 57 / 1370 cN |

| Bonding of wire | ||||||||

| Hot air bonding | 0.010-0.50mm | 0.010-0.50mm | 0.015-0.50mm | 0.015-0.50mm | 0.015-0.50mm | Limited | 0.015-0.50mm | 0.015-0.50mm |

| Oven bonding | 0.100-0.50mm | 0.100-0.50mm | 0.100-0.50mm | 0.100-0.50mm | 0.100-0.50mm | Limited | 0.100-0.50mm | 0.100-0.50mm |

| Resistance bonding | 0.100-0.50mm. | 0.100-0.50mm | 0.100-0.50mm | 0.100-0.50mm | 0.100-0.50mm | Limited | 0.100-0.50mm | 0.100-0.50mm |

| Solvent bonding | Not suitable | Not suitable | Not suitable | Not suitable | Not suitable | 0.015-0.50mm | Not suitable | Not suitable |

| Recommended solvent | --- | --- | --- | --- | --- | Ethanol/Methanol | --- | --- |

| Recommended bonding temperature | 150 - 170°C | 150 - 170°C | 180 - 200°C | 220°C | 220°C | 220°C | 220°C | 220°C |

| Resoftening temperature (after postbacking) | ≥ 125°C (180°C) | ≥ 125°C (180°C) | ≥ 145°C (190°C) | ≥ 230°C | ≥ 230°C | ≥ 210°C | ≥ 260°C | ≥ 260°C |

| Solderability | ||||||||

| acc. to IEC 60851-4 5. max . seconds at °C for 0.05 mm/0.25 mm, Grade 1B | 2.0s/390°C / 3.0s/390°C | 3.0s/390°C / 3.0s/390°C | 3.0s/390°C / 3.0s/390°C | 3.0s/390°C / 3.0s/390°C | Not solderable | 3.0s/390°C / 3.0s/390°C | 3.0s/390°C / 3.0s/390°C | Not solderable |

| ELEKTRISOLA-typical values IEC 60851-4 5. | ||||||||

| for 0.05 mm, Grade 1B, | 0.7s/370°C / 0.4s/390°C | 1.2s/390°C | 0.4s/420°C | 0.5s/470°C | --- | n.a/420°C | 0.6s/470°C | --- |

| seconds at °C | ||||||||

| for 0.25 mm, Grade 1B, | 1.2s/370°C / 0.7s/390°C | 1.5s/390°C | 0.8s/420°C | --- | --- | n.a/420°C | --- | --- |

| seconds at °C |

America

| Product-Code

|

ABN15

|

FS15

|

FSP18

|

FS18

|

AE21

|

AQ21

|

UT18

|

RT21

|

|---|---|---|---|---|---|---|---|---|

| General Description | ||||||||

| Base Coat / Base Coat Type | mod. Polyurethane+Polyamide | mod. Polyurethane | mod. Polyurethane | Polyesterimide | A200 + Polyamidimide | A200 + Polyamidimide | Polyesterimide | A200 + Polyamidimide |

| Bond Coat / Bond Coat Type | Polyvinylbutyral | Polyamide | Polyamide | Polyamide | Epoxy | Polyester | Polyamide | Aromatic Polyamide |

| NEMA (including the following norms) | MW136 | MW131 | MW137 | MW102 | MW102 | |||

| IEC (including the following norms) | IEC 60317-35, 60317-2 | IEC 60317-35, 60317-2 | IEC 60317-35 | IEC 60317-36 | IEC 60317-38 | IEC 60317-38 | IEC 60317-36 | IEC 60317-38 |

| Diameter Available | ||||||||

| AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-54 AWG | 24-58 AWG | 24-54 AWG | 24-54 AWG | 24-58 AWG |

| mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.01 - 0.50 mm | 0.015 - 0.50 mm | 0.01 - 0.50 mm | 0.015 - 0.50 mm | 0.015 - 0.50 mm | 0.01 - 0.50 mm |

| Properties | Low Bonding Temperature | Solvent Bonding Possible | Solvent bonding possible, higher thermal properties. | Solvent bonding possible, higher thermal properties. | Low bonding temperature & Solvent bonding possible. | High thermal and mechanical properties and high resoftening temperature. | High thermal and mechanical properties, high resoftening temperature. | Very high thermal and mechanical properties, very high resoftening temperature (non hygroscopic) |

| Shelf life in months (at 25°C / 60% rel. humidity) |

≤ 6 | ≤ 3 (hygroscopic) | ≤ 5 (hygroscopic) | ≤ 5 (hygroscopic) | ≤ 6 | ≤ 6 | ≤ 6 (Hygroscopic) | ≤ 6 |

| Applications | Stepper motors for watches, instrument coils, voice coils, sensors, transponders | Instrument coils, loudspeakers, small motors, sensors | Instrument coils, loudspeakers, small motors, sensors, transponders | High power speaker and receiver, micro speaker, high temperature applications | Instrument coils, loudspeakers, small motors, sensors, receiver and speaker for mobile phones | High power speaker and receiver, micro speaker, high temperature applications | High power speaker and receiver, micro speaker, high temperature applications | Motors, loudspeakers |

| Thermal Values of Base Coat | ||||||||

| Temperature index 20.000 h acc. To IEC 60172 | 158°C | 158°C | 192°C | 195°C | 212°C | 212°C | 195°C | 212°C |

| Cut-through Temperature | ||||||||

| Acc. to NEMA MW1000 3.5 for 44/30AWG: | ≥ 200°C / ≥ 200°C | ≥ 200°C / ≥ 200°C | ≥ 230°C / ≥ 230°C | ≥ 225°C | ≥ 320°C | ≥ 320°C | ≥ 265°C | ≥ 320°C |

| Elektrisola typical value for 44/30AWG: | 225°C / 230°C | 225°C / 230°C | 260°C / 265°C | 260°C / 265°C | 365°C / 380°C | 365°C / 380°C | 260°C / 265°C | 365°C / 380°C |

| Heat Shock | ||||||||

| Acc. To NEMA MW1000 3.5 for 44/30AWG: | ≥ 175°C / ≥ 175°C | ≥ 175°C / ≥ 175°C | ≥ 200°C / ≥ 200°C | ≥ 200°C | ≥ 220°C | ≥ 220°C | ≥ 200°C | ≥ 220°C |

| Elektrisola typical value for 44/30AWG: | 190°C / 180°C | 190°C / 180°C | 210°C / 200°C | 310°C / 320°C | 250°C / 240°C | 250°C / 240°C | 310°C / 320°C | 250°C / 240°C |

| Mechanical Values | ||||||||

| Elongation for Type 1 | ||||||||

| Acc. to NEMA MW1000 3.4 for 44/30AWG: | ≥ 10% / ≥ 22% | ≥ 10% / ≥ 22% | ≥ 10% / ≥ 22% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% | ≥ 14% / ≥ 25% |

| Elektrisola typical value for 44/30AWG: | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% | 23% / 40% |

| Bonding of Wire | ||||||||

| Hot Air Bonding | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG | 24-58 AWG |

| Oven Bonding | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG |

| Resistance Bonding | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG | 38-24 AWG |

| Solvent Bonding | Limited | Suitable | Suitable | Suitable | Suitable | Suitable | N/A | N/A |

| Recommended Solvent | Ethanol / Methanol | Ethanol / Methanol | Ethanol / Methanol | Ethanol / Methanol | Acetone/MEK | Acetone/MEK | ||

| Recommended Bonding Temperature | 120°C - 140°C | 150°C - 170°C | 150°C - 170°C | 180°C - 220°C | 120°C - 140°C | 160°C - 190°C | 180°C - 220°C | 200°C - 220°C |

| Resoftening Temperature for 30AWG | ≥ 100°C | ≥ 140°C | ≥ 170°C | ≥ 180°C | ≥ 100°C | ≥ 180°C | ≥ 180°C | ≥ 200°C |

| Solderability | ||||||||

| Solderability for Type 1 | ||||||||

| Acc. to NEMA MW1000 3.11 for 44/30AWG: | 2.0s/390°C / 3.0s/390°C | 2.0s/390°C / 3.0s/390°C | 2.0s/390°C / 3.0s/390°C | 2.0s/470°C / 3.0s/470°C | - | - | - | |

| Elektrisola typical value for 44 AWG: | 0.8s/390°C / 1.3s/370°C | 0.4s/390°C / 0.5s/370°C | 0.7s/390°C / 1.0s/370°C | 1.6s/470C | - | - | - | |

| Elektrisola typical value for 30 AWG: | 1.4s/390°C / 2.8s/370°C | 0.7s/390°C / 1.2s/370°C | 2.0s/390°C / 2.8s/370°C | 3.0s/470C | - | - | 5.5s/470C | - |

Elektrisola typical values are the result of various tests and represent average values.

We believe that all information in this catalogue is reliable and accurate, but the accuracy or completeness thereof is not guaranted.